Introduction

Today, many people enjoy protein bars as a quick snack or meal option. These bars are made from a mix of protein, nuts, oats, and other healthy ingredients. They give energy and are easy to carry anywhere. But one important part that people often forget is how these bars are made safely.

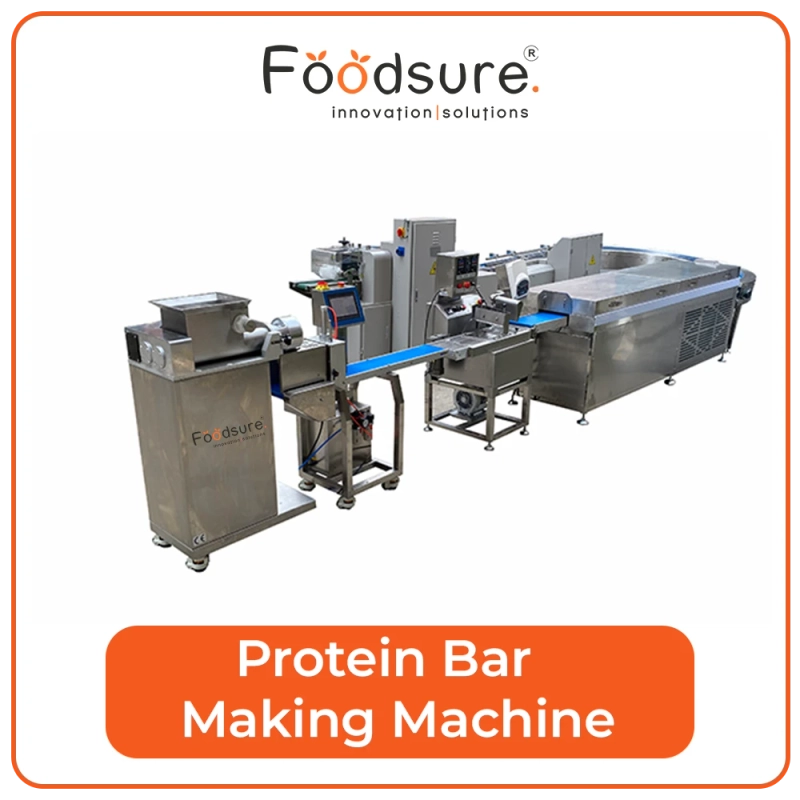

In every food factory, hygiene and safety are the most important things. A protein bar manufacturing machine plays a key role in keeping the food clean, safe, and fresh. This post explains, in very simple words, how hygiene and safety are maintained in the process of making protein bars, and why it matters for both workers and consumers.

1. Why Hygiene is Important in Protein Bar Making

Protein bars are made using ingredients that can spoil or get contaminated easily if not handled properly. If machines or surfaces are not clean, germs can mix with the food. This can lead to foodborne illness or bad taste.

Maintaining hygiene ensures that every protein bar is made in a clean environment. It protects the food, workers, and customers. Clean surroundings also help in keeping the machine in good condition and avoid breakdowns caused by residue build-up.

2. Clean Design of the Machine

A good protein bar manufacturing machine is designed in such a way that it can be cleaned easily. The parts that touch food are made of stainless steel, which does not rust and is easy to wash. There are no sharp corners or hidden gaps where food can get stuck.

After every batch of production, the machine is cleaned with warm water and mild cleaning agents. This ensures no leftover material stays inside. Some parts are removable, which helps in deep cleaning. This simple design helps maintain hygiene at all times.

3. Regular Cleaning and Inspection

In every food plant, regular cleaning schedules are followed. Operators clean the mixing bowls, rollers, and conveyor belts at fixed intervals. Before starting a new batch, the machine is checked properly to make sure it’s free from dust or old residue.

A checklist is usually maintained for cleaning tasks. This includes checking for leaks, removing stuck materials, and sanitizing surfaces. These small steps make a big difference in maintaining hygiene.

4. Temperature Control During Production

Temperature plays a very important role in food safety. When protein bars are being mixed or set, maintaining the right temperature helps avoid bacterial growth.

The protein bar manufacturing machine includes temperature controls in different sections like mixing, cooling, and packaging. For example, during cooling, bars are kept at a safe temperature so they don’t get spoiled.

This step keeps the texture soft and ensures freshness.

5. Safe Handling of Ingredients

Hygiene does not only depend on machines but also on how ingredients are handled. The ingredients are stored in dry and clean places. Workers wear gloves, masks, and caps to prevent contamination.

Before adding the ingredients to the machine, they are checked for freshness. Damaged or expired materials are discarded immediately. This process keeps the bars safe for eating and helps maintain trust in food quality.

6. Preventing Cross-Contamination

Cross-contamination means when one type of food touches another and transfers germs. For example, if nuts come in contact with unclean surfaces, it can affect the safety of other bars.

To prevent this, the protein bar machine is cleaned completely before using new ingredients or flavors. Some factories use separate machines for different products. This method ensures that there is no mix-up or allergy risk for consumers.

7. Safety Measures for Workers

Safety is equally important for the people who work with these machines. Operators are trained to handle machines properly. They are taught how to turn off power before cleaning, wear safety gear, and handle hot parts carefully.

Machines also have emergency buttons to stop production if something goes wrong. These safety systems help prevent injuries and accidents. A safe workplace also means better productivity and less downtime.

8. Regular Maintenance and Checks

A protein bar manufacturing machine needs regular maintenance to work smoothly. Maintenance means checking all parts for wear and tear, replacing old parts, and ensuring everything works properly.

When a machine is well-maintained, it not only keeps food clean but also avoids breakdowns. Maintenance schedules are usually fixed weekly or monthly, depending on production levels. It’s a simple way to keep both safety and quality in control.

9. Hygiene in Packaging

Once the bars are formed and cooled, they are packed. Packaging plays a key role in keeping bars fresh. The packaging area should be dust-free and dry.

The wrapping material is always food-grade and safe. Machines that seal the bars are also cleaned regularly. Workers avoid touching bars directly. This step makes sure the bars reach the consumer in perfect condition.

10. Following Food Safety Rules

Every food unit must follow certain food safety rules and guidelines. These may include proper labeling, regular inspections, and hygiene audits.

These rules ensure that all machines and workers follow good manufacturing practices. Cleanliness, temperature control, and safe handling are part of these standards. When all steps are followed, the final product is safe for everyone to consume.

11. Role of Modern Machines in Safe Production

Modern protein bar manufacturing machines are built with smart systems that help maintain hygiene. They have smooth designs, automatic cleaning systems, and sensors that detect any issues during production.

If you want to read more about food processing equipment and their setup .

It explains general information about machines used in making food products and how they help maintain hygiene.

Conclusion

Maintaining hygiene and safety in protein bar manufacturing is not just a rule — it’s a responsibility. From cleaning machines to checking ingredients and packaging, every step matters. The protein bar manufacturing machine helps make this process more consistent and clean.

With regular cleaning, safety training, and proper temperature control, both workers and consumers stay safe. Understanding these small but important details helps everyone see the care and effort that goes into making every protein bar.

Clean machines, safe handling, and proper maintenance are the foundation of good food production. When these are followed, the result is a healthy and reliable product that people can enjoy every day.