Electrical safety is one of the most critical aspects of any power system, yet it often receives attention only when something goes wrong. Grounding plays a vital role in ensuring that electrical installations remain safe, stable, and efficient. It helps redirect fault currents safely into the earth, preventing electrical shocks, equipment failure, and fire hazards.

Among the various materials used in grounding, the GI strip stands out for its efficiency and affordability. It has become a preferred choice for modern grounding systems across residential, commercial, and industrial sectors. Let’s explore why the GI strip is so important for an effective electrical grounding solution.

Understanding Electrical Grounding

Electrical grounding, also known as earthing, is the process of connecting electrical systems to the ground to ensure safety and system stability. This connection provides a low-resistance path for the dissipation of electrical faults or lightning surges.

The main goal of grounding is to maintain voltage levels within safe limits, protect equipment from overloads, and safeguard human life. Various grounding methods exist—rod earthing, plate earthing, and strip earthing—each chosen based on site conditions and system design. Among them, strip earthing using galvanized iron (GI) is widely adopted due to its practicality and cost-effectiveness.

What Is a GI Strip?

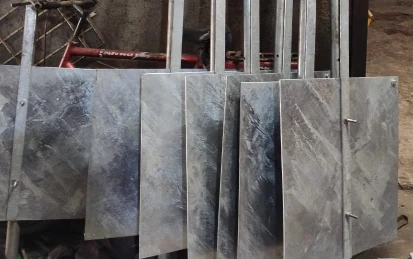

A GI strip (Galvanized Iron strip) is a flat metallic conductor made from mild steel and coated with a protective layer of zinc. This galvanization process prevents rusting and corrosion, making the strip ideal for outdoor and underground applications.

These strips come in various sizes, such as 25x3 mm or 50x6 mm, depending on the current-carrying requirement. Their primary function is to create a low-resistance path between electrical installations and the earth, ensuring that any excess or leakage current safely dissipates into the ground.

Think of the GI strip as the hidden backbone of your electrical safety system — strong, durable, and always ready to protect against electrical hazards.

Why Use a GI Strip for Grounding?

a. Excellent Corrosion Resistance

The zinc coating on the GI strip forms a protective barrier against oxidation and moisture. This makes it ideal for harsh environments, including coastal and industrial regions, where exposure to humidity and chemicals can cause corrosion.

b. High Electrical Conductivity

GI strips conduct fault currents efficiently, ensuring quick and reliable grounding performance. Their uniform structure allows consistent conductivity, reducing the chances of overheating or electrical faults.

c. Cost-Effective Solution

Compared to copper strips, GI strips are far more economical. They provide reliable performance without the high material cost, making them the preferred option for large-scale and budget-sensitive projects.

d. Long Life and Low Maintenance

Once installed, GI strips require minimal maintenance. The galvanization extends their service life, ensuring durability and stability even in underground conditions.

e. Mechanical Strength and Flexibility

GI strips offer excellent mechanical strength, making them easy to handle during installation. Their flexibility allows them to be bent or shaped according to the layout of electrical systems.

f. Compatibility with Multiple Systems

These strips integrate seamlessly with various grounding components such as rods, pits, and electrodes. They are suitable for residential complexes, data centres, industries, and high-rise buildings.

In short, GI strips deliver a balance of strength, conductivity, and cost-efficiency that makes them the most practical choice for modern electrical grounding systems.

Installation and Safety Tips

Proper installation is essential to ensure grounding effectiveness. Here are some best practices:

- Ensure the strip is directly connected to the electrode and soil with proper clamps or welding.

- Avoid coating or painting the strip surface, as this can increase resistance.

- Maintain the recommended burial depth to enhance durability and performance.

- Follow IS 3043 standards for earthing installations.

- Conduct periodic inspections to detect corrosion or loose joints.

For specialized setups, such as substation or transformer grounding, professionals may also consider GI plate earthing as an effective complement to strip systems.

Applications of GI Strip in Grounding Systems

GI strips are highly versatile and used across various sectors:

- Industrial Plants: Grounding for heavy machinery, control panels, and generators.

- Commercial Buildings: Safe earthing for distribution boards and HVAC systems.

- Residential Projects: Protection for household wiring and power systems.

- Renewable Energy Systems: Used in solar and wind installations for grounding panels and inverters.

- Telecommunication Towers: Helps prevent lightning damage and signal interference.

Their adaptability to different electrical configurations makes GI strips an integral part of every safe grounding setup.

Conclusion

Grounding is the foundation of electrical safety. Among all available materials, GI strips have proven to be a dependable and economical choice for establishing secure and durable earthing systems. Their corrosion resistance, conductivity, and long service life make them a trusted solution across industries.

At Genius Protection System Pvt. Ltd., we prioritize safety and performance in every project we undertake. Our expertise in electrical grounding solutions ensures that every installation meets the highest standards of reliability and efficiency. Choosing a high-quality GI strip is not just a technical decision—it’s a long-term investment in electrical safety and peace of mind.