In today’s competitive industrial landscape, automation is the driving force behind productivity and quality. Among the technologies leading this transformation arePallet wrapping machines and food processing machines. These innovative systems streamline packaging and production processes, helping businesses reduce waste, enhance efficiency, and maintain the highest hygiene and safety standards. Whether in the food industry, logistics, or manufacturing, these machines have become essential tools for success.

Understanding Pallet Wrapping Machines

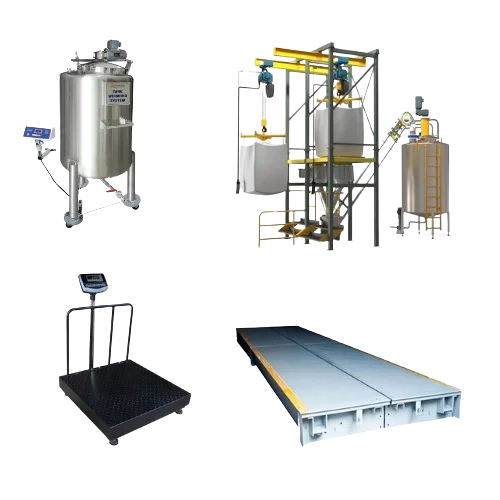

Pallet wrapping machines are designed to securely wrap palletized goods with stretch film, ensuring stability and protection during transportation and storage. Before automation, workers manually wrapped pallets—a slow, labor-intensive, and inconsistent process. With modern pallet wrapping machines, companies can now wrap loads quickly and uniformly, saving both time and material.

These machines come in several variants, including semi-automatic and fully automatic models. Semi-automatic pallet wrappers are ideal for small to medium operations, while automatic machines cater to large-scale production environments. Equipped with programmable settings and adjustable tension control, they deliver consistent wrapping quality that minimizes product damage.

One of the key advantages of pallet wrapping machines is their ability to reduce film wastage. They optimize stretch ratios to ensure just the right amount of film is used for each pallet. Moreover, they improve workplace safety by reducing the need for manual handling. In industries dealing with fragile or perishable goods—like food and beverage manufacturing—this consistent protection ensures that products reach consumers in perfect condition.

The Role of Food Processing Machines

Food processing machines are the heart of the food manufacturing industry. They automate tasks such as mixing, slicing, grinding, cooking, packaging, and sealing, allowing companies to handle high production volumes efficiently. These machines not only boost productivity but also uphold hygiene standards that are critical in food production.

Automation through food processing machines eliminates the inconsistencies of manual work, ensuring that every product meets the same quality standards. For example, automated mixers guarantee uniform texture, while precision slicers ensure equal portions—vital factors for consumer satisfaction and brand consistency.

Another significant benefit of modern food processing machines is improved safety. Designed with stainless steel and easy-to-clean components, they help prevent contamination and meet strict food safety regulations. Advanced models also integrate temperature and pressure controls, ensuring precise cooking and preservation without compromising nutritional value.

Integration of Pallet Wrapping and Food Processing Machines

When pallet wrapping machines and food processing machines work together, they create a seamless production-to-distribution flow. After the food is processed, cooked, and packaged, the next step is preparing it for shipment. Pallet wrapping machines step in at this stage to ensure the products are securely wrapped, stacked, and ready for transport.

For instance, in a dairy or frozen food plant, processed goods like cheese or ice cream are packaged and then placed on pallets. The wrapping machines protect these products from moisture, dust, and movement during transport. This integration ensures operational efficiency and product safety throughout the supply chain.

Additionally, this combination minimizes downtime. Modern systems can be synchronized so that once a food processing machine completes its cycle, the output automatically moves to packaging and then to pallet wrapping. This continuous workflow helps companies meet tight deadlines and customer demands efficiently.

Benefits of Automation in Food and Packaging

- Efficiency and Speed: Automated machines reduce manual labor and increase production output.

- Consistency: Both food processing and pallet wrapping machines deliver uniform results every time.

- Cost Savings: Lower labor costs, reduced material waste, and minimal product damage add up to substantial savings.

- Enhanced Hygiene: Automated systems minimize human contact, maintaining cleanliness and safety.

- Sustainability: Energy-efficient machines and optimized material use reduce the environmental footprint.

Technological Innovations Shaping the Future

The future of pallet wrapping machines and food processing machines lies in smart automation. Industry 4.0 technologies such as IoT, AI, and robotics are transforming how these machines operate. Smart pallet wrappers can now monitor film tension, detect load irregularities, and adjust settings automatically. Meanwhile, AI-driven food processing machines analyze data to maintain consistent quality and reduce resource usage.

Predictive maintenance is another innovation gaining traction. Sensors in both types of machines can identify early signs of wear, allowing technicians to perform maintenance before breakdowns occur. This reduces downtime and increases productivity.

In addition, sustainability is a major focus. Modern machines are designed to use less energy, reduce packaging waste, and operate with biodegradable materials—helping manufacturers meet eco-friendly production goals without sacrificing performance.

The combination of pallet wrapping machines and food processing machines represents the perfect blend of efficiency, safety, and innovation. Together, they streamline operations from the manufacturing floor to the loading dock, ensuring that food products are produced, packaged, and delivered with precision and care.

As industries continue to evolve, investing in these advanced systems is no longer optional—it’s essential. Businesses that adopt automated solutions gain a competitive edge, improving both their productivity and sustainability. From small-scale operations to large manufacturing plants, the integration of pallet wrapping and food processing technologies ensures a future where quality, safety, and efficiency go hand in hand.

By embracing automation, companies can achieve consistent results, reduce operational costs, and meet the growing demands of modern consumers. Ultimately, pallet wrapping machines and food processing machines are not just tools—they are the foundation of a smarter, more efficient industrial ecosystem.