Traceability rules the day in a situation where supply chains are enormous and recalls are expensive. Stickers as a means of identification are not enough anymore, and the contemporary manufacturing process demands exactness along with being ceaseless. Enter laser marking, the quiet powerhouse etching trust into every product. As an industry guru once said, "Traceability isn't just compliance; it's the pulse of transparent production."

Let’s explore why laser marking systems anchor today’s factories with unmatched reliability.

How the Laser Marking Process Ensures Lasting Identification

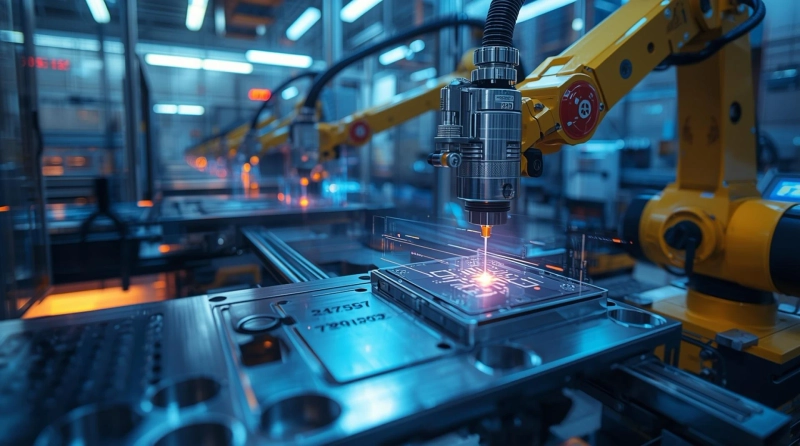

By employing a focused light beam, the laser marking process produces permanent identifiers such as barcodes or serial numbers. The identification marks created through the process of vaporizing or oxidizing the surfaces are high-contrast, durable, and able to withstand chemicals and extreme heat. The laser marking equipment operating on either fiber or UV technology from leading manufacturers delivers contact-free micron-level precision—no contamination and no tool wear involved. When combined with laser marking software, they create sophisticated designs, perfectly synchronizing with production lines for complete transparency throughout.

Commonly Marked Parts: Metal, Plastic, PCB, Medical Tools

Laser marking applications shine across diverse materials. Metals like steel get deep, scannable Data Matrix codes via fiber laser marking for automotive parts. Plastics, marked with UV lasers, grace electronics casings. PCBs rely on laser marking printers for tiny, damage-free identifiers. Medical tools, like implants, demand biocompatible etching for sterilization cycles. Key substrates include:

- Metals: Engine components, aerospace fittings—built for toughness.

- Plastics: Device shells, vials—clean and compliant.

- PCBs: Circuit codes—crucial for defect tracking.

- Medical Tools: Scalpels, prosthetics—safe and traceable.

This versatility makes laser marking solutions indispensable.

Advantages Over Labeling and Etching

Why lasers over labels or etching? Laser marking automation outpaces both with speed and finesse. Labels fade under UV or abrasion, risking data loss. Chemical etching leaves uneven marks and contaminants. A laser coder machine etches in seconds with zero residue, offering eco-friendly precision. While initial costs pinch, longevity saves: one automatic laser marking machine outlives countless labels. Paired with 2D imager readers, it ensures instant verification, cutting errors sharply.

Examples of Laser Marking Solutions for Traceability

Innovative laser marking systems redefine traceability. 3D laser marking machines use dynamic beam steering to etch curved surfaces like turbine blades, no fixtures needed. 3D vision systems enhance accuracy on complex geometries. High-volume lines leverage automatic laser marking machines from trusted laser marking machine suppliers, etching barcodes while laser inspection machines verify in real-time. Hybrid laser labeling machines blend etching and printing, ensuring robust tracking from factory to field.

Compliance with ISO and FDA Standards

Meeting ISO 15459 or the FDA’s UDI rules is non-negotiable. Laser marking manufacturers craft systems for 85% contrast and scanability, verified by laser inspection machines. Medical-grade etching on titanium tools uses biocompatible fibers, aligning with FDA standards. Laser marking services near me often provide certification support, ensuring audit-ready marks that streamline compliance and enhance safety.

Integration with MES and IIoT Systems

Laser marking automation thrives in smart factories. Linked to Manufacturing Execution Systems (MES) and Industrial Internet of Things (IIoT), laser logo machines feed serials to cloud dashboards, enabling real-time tracking. IIoT sensors trigger on-demand marking, while MES flags issues via 2D imager readers. For laser manufacturers in the USA, this modularity transforms production into a connected, predictive powerhouse.

Future Trends: Blockchain and Smart Serialization

The horizon glows with innovation. Blockchain pairs with 3D laser marking to etch cryptographic hashes, creating tamper-proof ledgers. Smart serialization embeds NFC chips alongside QR codes for dynamic updates. AI-driven laser marking near me hubs could cut energy use by 20%, while laser-marking parts with sensors herald autonomous factories.

Laser marking is the backbone of modern manufacturing, ensuring every part tells its story. For cutting-edge solutions, explore trusted providers like Mark Read Track, where 27 years of expertise deliver tailored laser marking solutions to elevate your operations.

Explore these related topics:

- Boost Your Production with Omron Barcode Verification: Top-Notch Label Inspection Solutions

- Boost Yield And Cut Costs: Why Auburn Hills Manufacturers Trust Mrt Barcode Reader Solutions

- How to Evaluate Barcode Verifier Sellers

- Why Direct Part Mark Code Reading is the Best Option

- Traceability Software Provider in Auburn Hills: Driving Manufacturing Excellence

- The Ultimate Guide to the Portable Handheld Laser Marking Machine

- Best Barcode Solutions in Auburn Hills: Complete Guide for Businesses in 2025

- What is the Difference Between Laser Marking and Dot Peen Marking