Regardless of your current needs, some materials are prevalent, while others are rare. Knowing the difference between the two can be very important.

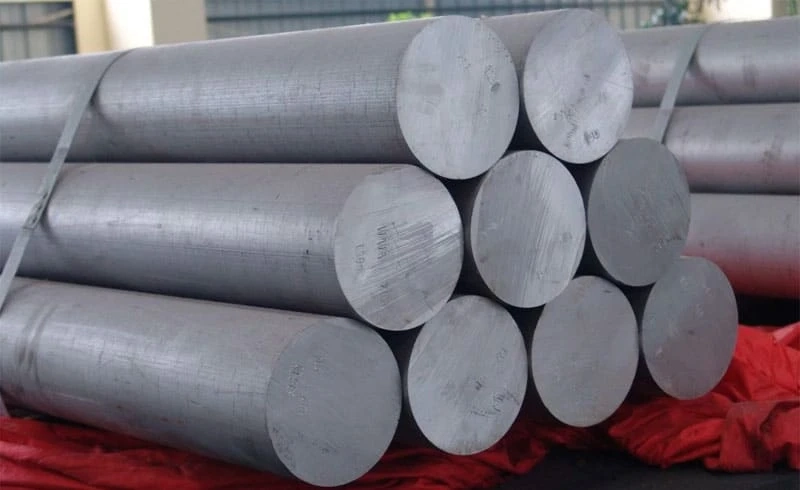

Features of ASTM A182 F22 Round Bars

Various industrial applications are dependent on the properties of ASTM A182 F22 Material. The material has high corrosion, oxidation and fatigue resistance and is often used as a base metal. Generally, it is used for piping in oil and gas, power stations, chemical plants, food processing plants, and many other industries. The chemical composition of ASTM A182 F22 Material includes manganese, chromium, silicon, and carbon. These elements are combined to form a chemical compound that improves the quality of chrome moly alloy forged fittings. ASTM A182 F22 bars have a wide range of sizes, enabling them to be used in different industries. They are made from alloy steel and are hardened by heating. Also, these bars are more potent and better suited for high-temperature applications than carbon steels. They are also available in a variety of shapes. They are used for various purposes, such as routing pipe equipment, joining dissimilar equipment, direction change, and branching pipe equipment.

Properties of F22 Round Bars

Various alloy steel grades, such as ASTM A182 F22, are used to manufacture bars. These are usually made from chromium-molybdenum alloys, which are more corrosion-resistant than carbon steel. The ASTM A182 F22 Material Properties also has a higher strength-to-weight ratio. They can be heat-treated or forged to meet the required dimensional and mechanical properties. They are suitable for high-temperature applications, such as boilers and power plants. They are also used for non-corrosive applications, such as food processing equipment. They are available in a wide range of sizes. The alloy grade of the steel bars is determined depending on the application. This grade is ideal for applications that require resistance to heat and corrosion.

Typical Applications of A182 F22 Round Bars

Alloy steel F22 bars are used in harsh environments, such as in corrosive atmospheres and high-temperature services. They are widely used in connectors and block valves. These are manufactured with a maximum of 2% to 2.5% chromium and are commonly used in parts of gas turbine engines, oil patch wellheads, and water supply systems. Some applications that use this material include power stations, food processing plants, and other industrial applications. It is also used in the transportation industry, especially in the petrochemical industry. In addition, alloying the steel, known as chrome-moly, improves the strength-to-weight ratio.