Fabricators perform multiple tasks, one that involves cutting metal. Perhaps your company cuts metal in-house, and maybe this is something you hire a professional to do. Regardless, it’s important to make quality and precision cuts. Based on the metal workpiece and product, the experts use predictive maintenance tools to achieve both of those goals.

With the right predictive maintenance products, fabricators can accomplish several things. One, as mentioned, has to do with making accurate cuts. Fabricators first go through a process-setting phase. That allows them to choose the necessary predictive maintenance tools and equipment to align the machining operations with the location of the part.

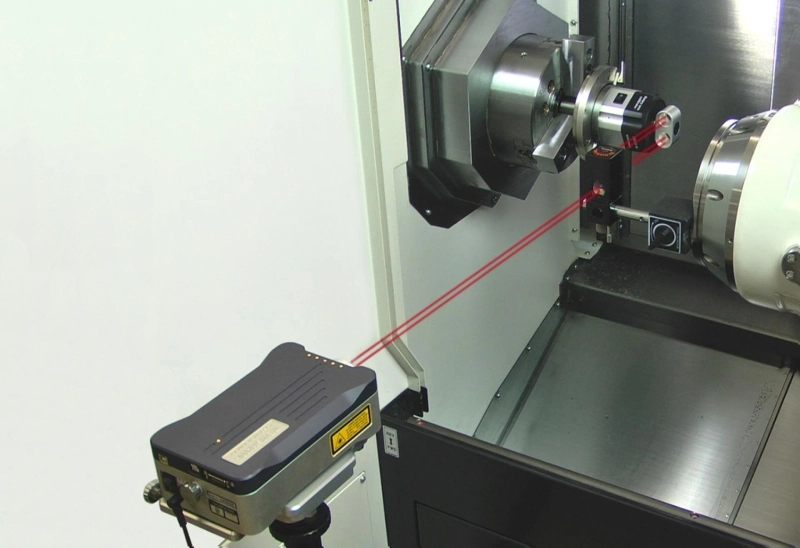

For instance, they can determine the length from the spindle-gauge line. That makes it easy to determine the height offset. From there, they can make sure the length falls within the specified tolerance. Also, using predictive maintenance tools before cutting metal allows them to identify the diameter while spinning so they know the tool size offset.

In addition, fabricators rely on predictive maintenance tools and equipment for the part-setting phase of a metal cutting project. In this case, they can identify the correct component, which aids in selecting the appropriate NC program.

Another benefit specific to the part setting phase is that experts can identify the right billet size. In turn, that helps them determine the condition of the material and the roughing cut sequence.

Using predictive maintenance products also proves beneficial for machine settings. These tools and equipment help with achieving the proper rotary axis alignment and positioning the center rotation of the indexer. All of these things combined lead to more precise cuts.

Advanced Controls for Predictive Maintenance Tools

To get the most out of predictive maintenance tools and equipment, you must use the highest quality products available. As a result, you’ll have better controls, which further enhances the metal cutting process. Below are a few examples of the controls that matter the most.

- Automated Settings – Most of the tools and equipment used by fabricators feature automation. The best predictive maintenance products boast automated settings for probing. That makes the probing process up to 10 times faster compared to manual methods. So you’ll have more time for the metal cutting portion of the project, which in turn also enhances overall quality and precision.

- Workpiece Inspection Probes – High-tech equipment automatically measures both the position and alignment of the component.

- Tool Setters – Advanced products have tool setters. These enable the dynamic setting on cutting tools associated with a machine tool. For instance, Renshaw has an innovative tool setter called Productivity+™. As part of the design of its predictive maintenance products, this enables the part and tool setting to ensure seamless integration with the process of cutting metal.

Make Every Cut Count

For in-house metal cutting, contact us at Maintenance Diagnostic System, Inc. (MDS). We’ll help you select the right predictive maintenance tools and equipment. We also provide metal cutting services, if needed.