In today’s competitive industrial environment, manufacturers face constant pressure to optimize operations, reduce costs, and deliver high-quality products on time. One of the most powerful tools to achieve this is ERP for manufacturing. Unlike generic ERP systems, manufacturing-specific ERP solutions are tailored to handle the complexities of production, supply chain, inventory, quality control, and workforce management—under one centralized system.

ERP for manufacturing not only improves visibility across departments but also empowers data-driven decision-making, automation, and seamless coordination between functions. In this blog, we’ll dive into why ERP is essential for the manufacturing sector and explore the key modules every manufacturer should have.

What Is ERP for Manufacturing?

ERP software for manufacturing is a comprehensive software solution designed to manage and integrate core business processes specific to manufacturing operations. From procurement to production, sales to shipping, and finance to HR, a manufacturing ERP brings everything together in one system.

This integration results in:

- Reduced operational silos

- Better inventory control

- Real-time production tracking

- Cost savings through process optimization

- Increased customer satisfaction

Companies like Lighthouse Info Systems provide customized ERP solutions that align with the unique needs of various manufacturing segments, including steel, engineering, batch processing, and discrete manufacturing.

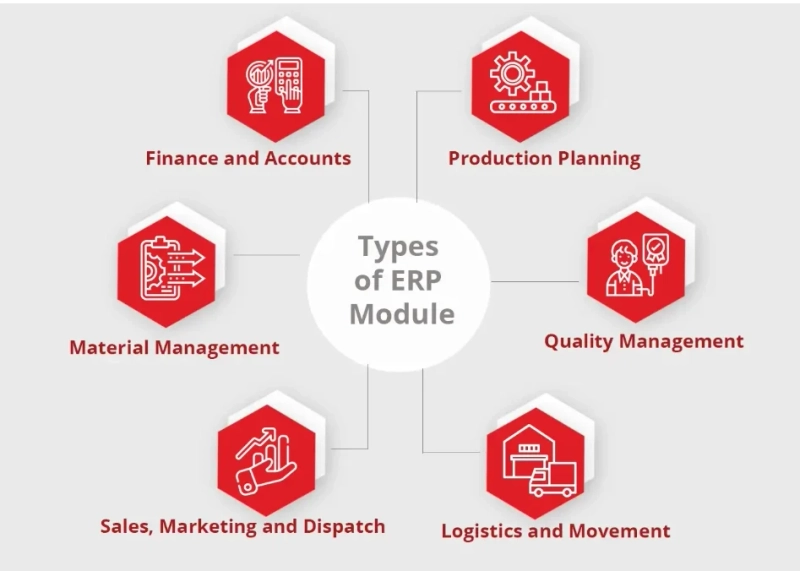

Essential ERP Modules for Manufacturing

Let’s explore the most important ERP modules that help manufacturers streamline operations and stay competitive.

1. Production Planning and Control

The production module is at the heart of ERP for manufacturing. It helps manufacturers create production schedules, manage resources, and monitor shop floor operations in real-time.

Features include:

- Bill of Materials (BOM)

- Work order and routing management

- Capacity planning

- Production tracking and reporting

- Shop floor data collection

With this module, manufacturers can avoid bottlenecks, reduce downtime, and meet delivery deadlines consistently.

2. Inventory and Material Management

Managing raw materials, WIP (Work-in-Progress), and finished goods is critical. This module provides full visibility into stock levels across multiple warehouses.

Key functionalities:

- Material Requirement Planning (MRP)

- Stock transfers and adjustments

- Batch and serial number tracking

- Real-time inventory valuation

- Warehouse space optimization

ERP for manufacturing ensures that the right material is available at the right time—reducing delays and excess inventory.

3. Procurement and Supplier Management

Efficient procurement is essential for smooth production. This module automates and streamlines the purchasing cycle.

Benefits include:

- Automated purchase requisitions and orders

- Vendor performance tracking

- Supplier price comparisons

- Purchase approvals and workflows

- Integration with inventory and finance

Manufacturers can build strong supplier relationships and reduce procurement costs with greater control and visibility.

4. Sales and Distribution

This module helps manage the entire order-to-cash process, ensuring timely delivery and accurate billing.

Core features:

- Sales order management

- Price lists and discounts

- Shipping and logistics integration

- Customer communications

- Real-time stock availability checks

By connecting sales with inventory and production, ERP for manufacturing helps set realistic delivery timelines and improves customer satisfaction.

5. Quality Management

Maintaining product quality is crucial in manufacturing. This module ensures quality checks are enforced at every stage—from procurement to final delivery.

What it offers:

- Quality inspection plans

- In-process and post-production checks

- Non-conformance tracking

- Compliance documentation

- Corrective and preventive actions (CAPA)

Lighthouse ERP includes powerful tools to embed quality assurance throughout the production lifecycle.

6. Finance and Accounting

No business can function without financial clarity. This module manages all accounting functions and ensures compliance with local regulations.

Includes:

- General ledger and journal entries

- Accounts payable/receivable

- GST, TDS, and tax compliance

- Financial reporting and audits

- Cost center and project accounting

Integration with other ERP modules helps manufacturers understand the financial impact of every operation in real time.

7. Human Resource Management (HRM)

From labor-intensive processes to shift management, HR plays a critical role in manufacturing.

Features include:

- Payroll and attendance

- Shift scheduling

- Leave management

- Performance reviews

- Compliance with labor laws

With integrated HRM, manufacturers can efficiently manage workforce productivity and maintain employee satisfaction.

Final Thoughts

Implementing an ERP for manufacturing industry is not just about automating tasks—it's about transforming your business for long-term success. Whether you're a discrete manufacturer, a process-based operation, or work in a hybrid model, having the right ERP modules can significantly enhance efficiency, reduce costs, and improve product quality.

At Lighthouse Info Systems, we specialize in providing scalable, industry-specific ERP solutions designed to meet the unique needs of manufacturers. Our ERP modules are built to drive operational excellence from the shop floor to the boardroom.