Whether you’re in the automotive, IT, crafts, or consumer goods industry, you would require premium quality die-cutting equipment to facilitate a smooth product manufacturing process. A die is a shaped blade that cuts through materials to give them identical cuts. Die-cutting is a versatile and effective cutting method used in various applications. The best part of die-cutting equipment is you only require a single machine, and the die can be changed to meet diverse requirements.

Brands can also get a customized die that can perform multiple functions like curling, bending, coining, etc. If you have one project in hand, you should consider employing the services of a company offering die-cutting services. But if you’re planning to go scale and require die-cutting machines frequently, investing in the best available equipment is the best. To help you purchase the ideal machine, we’ve curated this epic guide featuring the different types of die-cutting equipment. So let’s quickly check out the various equipment types shared below.

Matched Metal Die-cutting

The matched metal die-cutting machine is all you need if your company requires materials to get an intricate and complex shape. This equipment is known for its unmatched tolerance and excellent handling of complex shapes. You should proceed with matched metal die-cutting equipment if you require small features. This machine contains two dies designed in the female/male format to ensure you get the highest precision level. Such cutting is generally done on a flatbed.

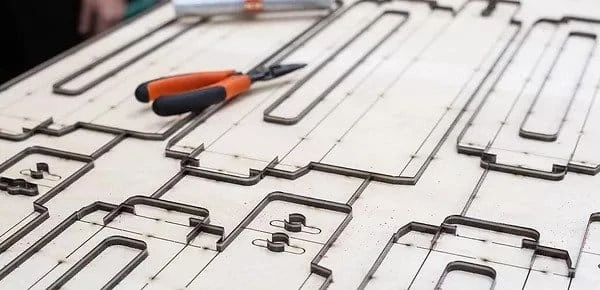

Steel Rule Die-cutting

Also known as flat-bed die-cutting equipment, this machine is used for precise stamping and cutting. This equipment utilizes servo-controlled presses or manual handfed presses. The only downside of the steel rule die-cutting machine is it’s not as accurate as a rotary die-cutting machine, but it does an excellent job dealing with massive material chunks. If the material you’re using is too thick, the steel rule die-cutting equipment can perform better than the rotary die-cutting machine.

Rotary Die-cutting Machine

One of the most popular die-cutting machines is rotary die-cutter equipment. Rotary die-cutting equipment is extremely precise, detail-oriented, and fast. It can cut multiple layers simultaneously while ensuring the intricate details and requirements are met. If you deal in high volume, this equipment can help you quickly scale your production. The only problem associated with this equipment is its expensive cost. Rotary die-cutter machines don’t come cheap, but their results make the investment worth every penny spent.

Clean Room Die-cutting

It is ideally used in the medical industry and by companies that manufacture medical supplies. This machine is generally placed in a controlled and clean environment, wherein the airflow is controlled for bacteria-free surroundings. Skilled and trained professionals are always in the room, monitoring the humidity and temperature levels for the best results.

Rotary Matched Metal Die-cutting

Want complex parts cut with numerous layers? If you answered yes, this equipment is for you. The rotary-matched metal die-cutting is the most versatile machine you can get. It utilizes rotary die-cutting for faster output without compromising the quality levels. Besides precise cutting, the equipment offers slitting, in-line laminating, adhesive coating, etc. Rotary-matched metal die-cutting machines are also known to perform the same function as matched metal die-cutting equipment.

Specialized Dies

Now that you’re aware of the common types of die-cutting machines available, it’s time to learn about the different dies that can be purchased separately and placed in the die-cutting equipment to achieve specific results. The different types of a die are shared below:

Blanking die - is used to get a precise, smooth, and flat finish on materials. These dies are used to cut a particular distance from the edge to achieve the desired shape. Blanking dies are in high demand because of their precise cutting and fast mechanism.

Broaching - if your work requires cutting thicker materials, rotary die cutters might not be enough for the task. Some materials can also be too tough for specific traditional die-cutting machines. It is where the use of broaching die comes into use. These dies have sharp cutting teeth that can easily cut through any material, irrespective of their thickness and toughness.

Bending - as the name suggests, bending dies are used to create a specific bend angle for the desired material. It can bend to the desired degree whenever the right amount of pressure is exerted on a material. Bending dies are specifically added to die-cutting machines to create bent angles up to ninety degrees for getting the perfect ‘L’ shaped brackets. Companies use this die to ensure the same degree of bend and angle is achieved multiple times.

Coining - companies use coining dies to punch precise and identical circular holes into the given material. These dies are combined with a punch which can provide extremely high accuracy levels. It can be useful when dealing with complex shapes that require identical cuts every time.

Bulging - is primarily used to give a particular shape to cylindrical items like pipes. These dies use oil, water, or other liquid material inside a rubber block which is pressurized to alter the shape of a given material.

Get the Right Die-cutting Equipment for Best Results

Now that we’ve listed all the common types of die-cutting machines in the market finding the right equipment won’t be challenging. The market offers a wide range of die-cutting equipment and individual dies to achieve particular tasks. But knowing which die and equipment are best for specific tasks can make your entire work easier. Not all die-cutting machines are created equal, so investing in the right machine is essential.

0