In electrical or electronic circuits, one of the most commonly used "passive devices" is a resistor. Because of their wide range of applications, they exist in different varieties. Depending on the type of resistance they provide, these devices are usually classified as fixed or variable resistors. However, whether the resistance is fixed or variable, the structure is different. So we named them according to their structure type. Carbon film resistors are one type of resistance.

What is a Carbon Film Resistor?

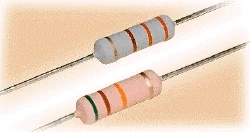

It is clear from the name "carbon film resistor" itself that this type of resistor is made of the carbon film. The carbon film is deposited on the ceramic precursor. This is actually a fixed type of resistor, which means that it only provides a resistance value. The function of the carbon film is to limit the current flow in the circuit. We can define carbon film resistors as Carbon film resistor is fixed resistor. It uses a carbon film deposited on a ceramic precursor to limit the flow of current.

The accuracy of the resistance value provided by this type of resistor is due to the spiral cut that is usually made into a thin film. This and other architectural features are discussed in the "Construction" section of this article.

Now, this resistor has a special symbol to indicate its schematic diagram, you might think. In fact, this symbol is the same as the symbol for resistors, zigzag lines, or rectangular boxes (IEC standard).

When using carbon film resistors in the circuit, we use "CR" to indicate. For example, if we used a 120 KΩ carbon film resistor, then we would write it as CR120kΩ to represent the same situation.

Carbon film resistors are built or manufactured using a deposition process. Its ceramic substrate is a carbon film. This carbon film restricts flow and is, therefore, an essential part of this resistance. It is for this reason that the resistor is named "carbon film resistor". A hydrocarbon, such as methane or benzene, cracks at a high temperature of 1,000 degrees Celsius, where the ceramic carrier is broken. Since pure graphite (carbon) is used for distribution on the ceramic substrate without being combined with it, the noise generated by the carbon film resistor is very low. The role of the ceramic substrate is the heat or electricity of the insulator. Therefore, its existence enables this resistor to withstand high temperatures without causing great damage.

For more relevant about how does the carbon film help limit the flow of electrons is here:

https://www.easybom.com/blog/a/what-is-carbon-film-resistors

0