Damascus knives are known worldwide for their strength and aesthetic appeal. They are used in the best of the best Japanese knives due to their strength and other unique characteristics.

Damascus knives get the name from the special steel used in the blades of such knives.

Damascus steel, also known as Persian water steel, is very strong steel with beautiful artisan patterns etched into it due to its manufacturing process. Ita very sharp, adamant, and overall, and most other alloys don’t even come close in strength.

The manufacturing process for a real Damascus paring knife is highly complex and challenging to sustain, hence the high cost. Several layers of steel and iron are layered together by an expert blacksmith who forges them into one using extremely high temperature and heavy hammers. Forge welding is the reason for the watery patterns on Damascus steel. Damascus steel was earlier known as wootz steel. Damascus steel is the modern interpretation of wootz steel since the original manufacturing process for wootz steel was lost in time.

High carbon steel is necessary for Damascus steel. The quenching process required for any knife to be strong and resilient is also a complex procedure for Damascus since, without due care, a quench could crack the steel into two. The quenching process is done in a very controlled manner by an artisan to ensure uniform cooling; when done correctly, Damascus steel becomes extremely strong.

The patterns on Damascus steel, which most people use to recognize, vary from blacksmith to blacksmith and are well-kept trade secrets and challenging to replicate in any way. Depending on the forging and quenching process and the types of steel used for layering, different colors and unique patterns can be easily engraved into Damascus steel. An artisan blacksmith can make Damascus knives with such beautiful designs that it resembles artwork more than a piece of cutlery.

These characteristics play an important role in why Damascus knives are preferred for painting knives and other knives that want to reach the highest levels of strength and quality. The blades tend to retain their sharpness and hence tend to last for a long time.

Japanese knife makers use Damascus in their blades, for example, to reach the highest levels of quality aesthetics, functionality, and longevity.

What is a paring knife?

A paring knife is a small knife used for precision work in the kitchen, like a fillet knife. They are very agile and tend to have fragile blades to ensure precision cuts like deveining shrimp, thinly cut vegetables, and filleting fish. It is used for delicate jobs, and its blade is no more than 2 to 4 inches long at the most.

Pros and Cons of Damascus steel paring knife

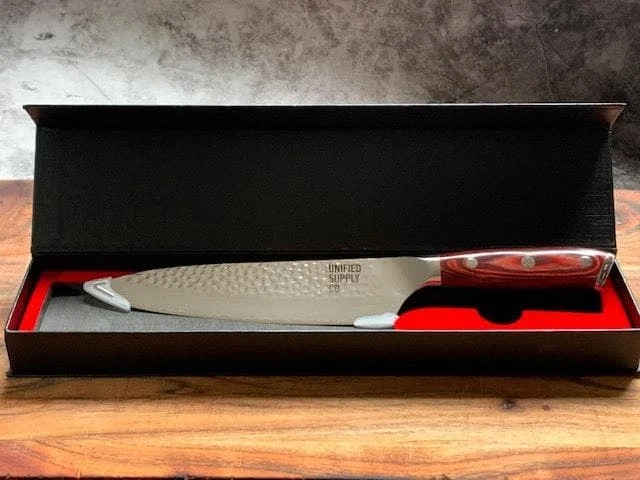

There are multiple reasons why chefs love Damascus steel paring knife. From their beauty to finesse, agility, and aesthetic craft, there are numerous pros to these knives:

- Very thin

- Strong

- Agile

- Aesthetic

- Will last for a considerable amount of time

- These knives are available in a variety of different shapes and sizes.

Cons

- Very Expensive due to the expertise of the artisans involved in shaping Damascus steel and Damascus knives.

- These can easily rust due to the procedures involved in constructing the knife. These knives will be ruined if exposed to organic materials and without proper care. Thus, the maintenance and care involved in ensuring that the knife works seamlessly, you need to follow the guidelines to take care of the knives.

- Due to the high volume of pairing knives required in a kitchen, most hotels will find it uneconomical to use Damascus pairing knives.

0