What are 3 Modern Power Looms- Types, Advantages & Uses

The textile manufacturing industry in India is growing rapidly because of the changing trends and preferences related to fashion and clothing. Earlier, all the fabrics were made by hand, and it took a lot of time. But in today’s era, various technological and machinery innovations have been introduced that have made it much easier to make different kinds of fabrics, laces, and materials. The power loom is one of the most famous and well-known innovations in the textile industry. This technology is used to make fabrics with a variety of textures and fabrics. This revolutionary tool also allows the industry to make the fabrics easily, efficiently, and very quickly. Weaving looms have been on the market since the first century, but their large size and slow speed have caused numerous environmental and human health problems.But the invention of power looms has changed this scenario, and the mass production of fabrics is now a reality.

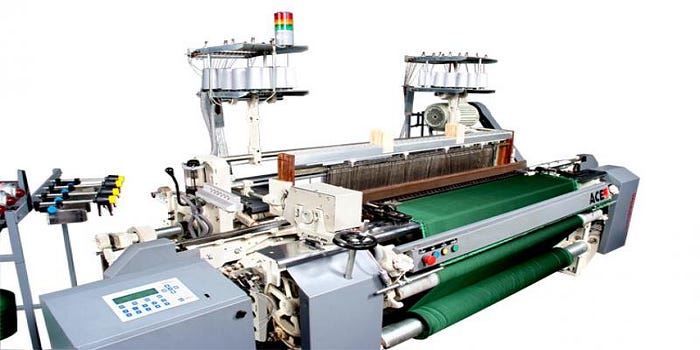

Modern power looms are faster, smaller, and more efficient than the earlier designs of machines. Let’s have a look at some modern power looms:

Electronic Jacquard Loom Machine: The jacquard is a widely used textile industrial instrument, hence known as a crucial part of the Textile Manufacturing Industry in India. Moreover; this represents a significant advancement in the history of textile manufacturing. Electronic Jacquard Loom Machine uses a continuous chain of punch cards located at the looms to effectively regulate the lifting of the individual threads. This machine is able to produce multiple designs and patterns of fabrics at a single time by simply altering punching cards.

Advantages

It has high speed and it doesn’t require any kind of dynamic forces as required in the conventional loom. The weft insertion rate of this machine is higher as compared to the conventional loom. Moreover, this insertion rate is influenced by the weft control. This is fully automatic and you don’t even need to cut the weft waste or weft selvedge.

Use

This machine is capable of producing high-end fabrics with effective and intricate patterns. They are also used to weave damask, brocade and weave tapestry. They are also popular for weaving patterned knitted fabrics in large quantities.

Water Jet Loom Machine: A water jet loom machine is mainly used for weaving clothes and materials. This machine uses a water jet to insert the weft into the warp. The force of water brings the yarn from one side to the other. Rapier Loom machine is mainly used in East Asia. This machine is widely used because of its low energy consumption and high insertion performance.

Advantages

- Long Engine life

- supple and quiet

- Insertion is simple

- Ecellent manoeuvrability.

- Require less maintenance.

Use

Water jet weaving is only appropriate for hydrophobic yarns such as polyester PET, polyamides, and acetate C.A. They are not suitable for natural hydrophilic fibres such as cotton, hemp, nettle etc.

Bullet Looms: The bullet loom is loaded with a ball bearing base and a spherical base that enables high loom-RPM for the machine. The bullet looms are mainly used to produce fabrics at a fast rate while maintaining quality and ensuring smooth transmission. This bullet loom machine is able to run at a speed of up to 180 RPM without harming the other parts of the machine or weaving.

Advantage

- Low maintenance

- Low energy consumption

- High-speed weaving

- Effective production

- Higher RPM

- Heavy reed pick

Use

The Bullet loom is the widely used and most preferred choice of power loom weavers because of its effective production and low power consumption. This is mainly used to make high-end fabrics, conventional items, and daily wear.

If you are also looking for a Textile Machine manufacturer in India, then get in touch with Weavetech. They are providing the most energy-efficient weaving and twisting solutions.