Cathodic protection contractors systems prevent corrosion from damaging key equipment and machineries. This extends the life of structures and equipment, saving companies money over time. There are two main types of cathodic protection: galvanic and impressed current. Each type is used for specific applications and conditions.

Reliability

Cathodic Protection Contractors are a crucial part of the long-term success of any concrete construction project. They add value to projects, and they also provide a service that clients can enjoy for the long term.

CP systems stop the corrosion cycle that can lead to premature failure of structures. This extends the life of the structure indefinitely and reduces costs for periodic maintenance and repairs.

The corrosion of metallic components is the leading cause of premature failure in many civil and industrial structures. CP systems are used to extend the life of pipelines, oil and gas infrastructure and marine structures.

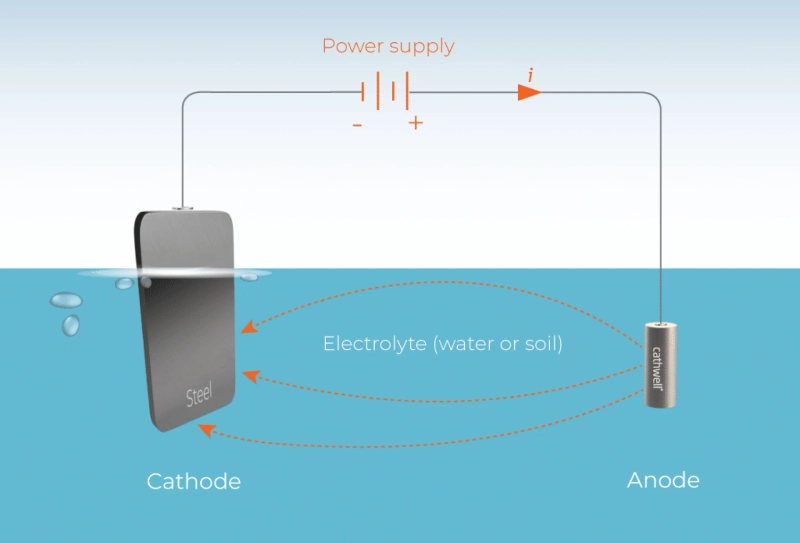

Both galvanic anode (GACP) and impressed current cathodic protection (ICCP) are highly effective in extending the life of these structures. GACP is the more common approach offshore but ICCP is increasingly being used for steel in concrete applications.

Safety

Cathodic protection contractors is a specialised field that requires a trained, qualified engineer with the appropriate level of expertise. This means that the design, installation and testing of cathodic protection must be carried out by a specialist who has been trained in the area.

A cathodic protection system is often used in combination with other forms of corrosion control, such as coatings. This is because the protective effects of cathodic protection are only optimal within a narrow range of design and operational parameters.

The two most common methods of cathodic protection are galvanic (sacrificial) and impressed current. The former relies on the galvanic series potentials of metals to drive cathodic protection current from an anode to the structure being protected.

Cost

cathodic protection contractors is a proven technique to protect concrete structures from corrosion. This is particularly true of concrete rebar which is a key component of reinforced concrete structures, such as bridges and highway culverts.

Corrosion of rebar is a major cause of premature failure for highway, waterway and marine structures. Repairing damaged concrete alone is not a long-term solution, and can often result in additional corrosion within years.

The most effective and economical solution is to install a cathodic protection system. These systems are robust, utilise state of the art control electronics and have a performance history in excess of 20 years.

These types of systems are used to protect steel pipes, storage tanks, structural piles and other buried or submerged metal surfaces. They can be used with both galvanic anodes and impressed current methods, depending on the required current, soil resistivity and the type of structure to be protected.

Time

The time it takes to complete a Cathodic Protection Contractors job depends on how large the job is. Smaller jobs can be completed by a single technician while larger projects require a team of technicians.

The CP process is an effective way to stop the corrosion of concrete that has been penetrated by sea salt or a corrosive agent like carbon dioxide. It is more cost-effective than conventional repair methods that involve removing all of the damaged concrete and replacing it with new material.

CP is also the best solution for structures that are severely damaged and are likely to be re-contaminated by ground water or by chemicals. A properly designed and operated CP system can extend the life of a structure indefinitely.