Two-stroke engines, celebrated for their simplicity, power, and lightweight design, are employed across a myriad of applications, from motorcycles and ATVs to chainsaws and outboard motors. Despite their ubiquity and versatility, maintaining optimal lubrication within two-stroke engines is a critical yet often neglected aspect. Inadequate lubrication can lead to premature wear, diminished performance, and even catastrophic engine failure. Understanding the intricacies of different lubrication systems and adhering to their maintenance requirements is paramount for ensuring the longevity and efficiency of two-stroke engines. In this detailed exposition, we will delve into the nuances of two-stroke engine lubrication systems, exploring their types, advantages, disadvantages, and the maintenance procedures required to ensure optimal engine performance and longevity.

Types of Two-Stroke Engine Lubrication Systems

Two-stroke engines predominantly employ two distinct types of lubrication systems: pre-mix lubrication and oil injection lubrication. Each system presents its unique characteristics, necessitating tailored maintenance approaches.

1. Pre-Mix Lubrication:

Pre-mix lubrication, also known as fuel-oil mixing, stands as the conventional method of lubricating two-stroke engines. In this system, the lubricating oil is manually blended with the fuel in specific ratios before being added to the engine\'s fuel tank. Once mixed, the oil and fuel concoction traverse into the engine\'s combustion chamber, where it dutifully lubricates engine components throughout the combustion process.

Advantages:

- Simplicity: Pre-mix lubrication boasts a straightforward configuration, devoid of additional components.

- Control: Operators exercise meticulous control over the oil-to-fuel ratio, facilitating customization based on engine requisites and performance preferences.

- Versatility: Applicable across a broad spectrum of two-stroke engines, including vintage models and those devoid of oil injection systems.

Disadvantages:

- Manual Mixing: Mandates precise measurement and mixing of oil and fuel, heightening the risk of incorrect ratios.

- Potential Pitfalls: Incorrect oil-to-fuel ratios precipitate engine maladies, including damage, carbon accumulation, and fouled spark plugs.

- Messiness: The manual blending of oil and fuel may be messy and inconvenient, particularly during refueling endeavors.

2. Oil Injection Lubrication:

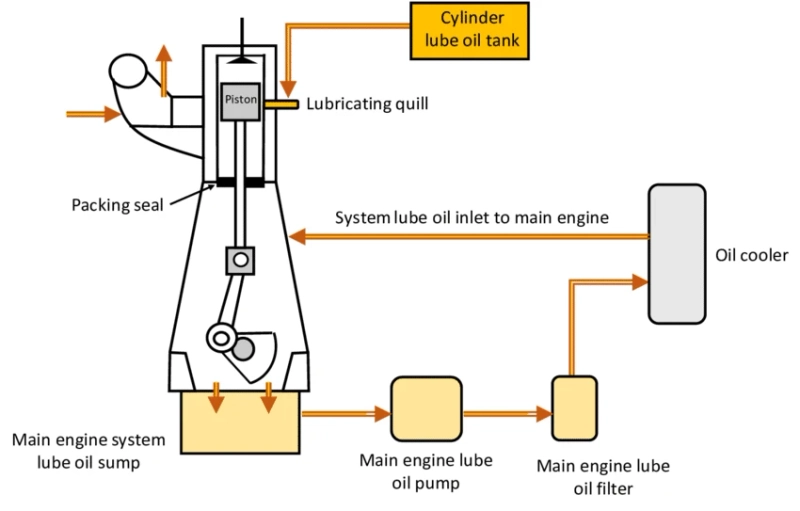

Oil injection lubrication is a more sophisticated alternative, automating the injection of lubricating oil into the engine\'s intake air or directly into the combustion chamber. This system typically encompasses components such as an oil pump and injector, orchestrating the precise delivery of oil contingent on engine speed and load.

Advantages:

- Automated Delivery: Oil injection systems provide automatic and precise oil delivery, eliminating the need for manual mixing.

- Accuracy: Ensures accurate oil-to-fuel ratios under fluctuating operational conditions, mitigating the risk of engine adversities.

- Reduced Buildup: Minimizes carbon deposition and spark plug fouling associated with erroneous oil-to-fuel ratios.

Disadvantages:

- Complexity: Oil injection systems entail supplementary components and heightened intricacy compared to pre-mix systems, augmenting the potential for system malfunctions.

- Maintenance: Regular upkeep is imperative to safeguard the seamless operation of oil injection components, encompassing pumps and injectors.

- Compatibility: May not be suitable for antiquated engines or those constrained by spatial limitations for extra components.

Maintenance Requirements for Two-Stroke Engine Lubrication Systems

Proper maintenance is crucial to ensure the longevity, performance, and reliability of two-stroke engines. The lubrication system plays a critical role in this regard, and specific maintenance tasks are necessary to keep it functioning optimally. Here, we\'ll delve into the maintenance requirements for both pre-mix and oil injection lubrication systems in greater detail:

1. Oil Quality and Ratio:

Pre-Mix Lubrication:

- Oil Selection: Choose a high-quality two-stroke engine oil that meets the engine manufacturer\'s specifications.

- Correct Ratio: Follow the manufacturer\'s recommendations for the oil-to-fuel ratio precisely. Deviating from this ratio can lead to inadequate lubrication or engine damage.

- Mixing: Ensure thorough mixing of oil and fuel to achieve a homogeneous mixture. Inadequate mixing can result in uneven lubrication and engine performance issues.

Oil Injection Lubrication:

- Oil Compatibility: Use oil specifically designed for oil injection systems to prevent clogging or damage to the injection components.

- Monitor Oil Levels: Regularly check the oil reservoir to ensure an adequate supply of oil. Low oil levels can lead to insufficient lubrication and engine damage.

- Oil Pump Inspection: Periodically inspect the oil pump for proper operation and signs of wear. A malfunctioning oil pump can lead to inadequate lubrication or oil delivery issues.

2. Oil Injection System Inspection:

Oil Injection Lubrication:

- Component Check: Inspect all components of the oil injection system, including lines, fittings, pumps, and injectors, for signs of wear, damage, or leaks.

- Cleanliness: Ensure that the oil injection system is free from debris or contaminants that could obstruct oil flow or damage components.

- Seals and Gaskets: Check seals and gaskets for leaks and replace them as needed to prevent oil leakage and ensure proper lubrication.

3. Oil Pump Adjustment:

Oil Injection Lubrication:

- Optimal Settings: Periodically check and adjust the oil pump settings according to the manufacturer\'s specifications. This ensures that the correct amount of oil is delivered to the engine at all operating conditions.

- Synchronization: Verify that the oil pump is synchronized with the engine\'s speed and load to maintain proper lubrication under varying conditions.

4. Spark Plug Inspection and Cleaning:

- Regular Inspection: Routinely inspect the spark plug for signs of fouling, carbon buildup, or oil deposits. A fouled spark plug can lead to poor engine performance and inefficient combustion.

- Cleaning: Clean the spark plug using a wire brush or spark plug cleaner to remove deposits and ensure proper ignition. Replace the spark plug if cleaning is ineffective or if it shows signs of damage.

5. Engine Overhaul:

- Periodic Overhaul: Consider performing a comprehensive engine overhaul at regular intervals, especially for engines subjected to heavy use or extended periods of operation.

- Component Replacement: Replace worn or damaged engine components such as piston rings, bearings, seals, and gaskets during the overhaul to restore engine performance and reliability.

- Cylinder Inspection: Inspect the cylinder bore and piston for signs of wear, scoring, or damage. Address any issues found during the overhaul process to prevent further damage to the engine.

Conclusion

Adequate lubrication is pivotal for optimizing the longevity, efficiency, and performance of two-stroke engines. Whether availing pre-mix or oil injection lubrication systems, strict adherence to maintenance requisites is critical to prevent engine calamities and optimize functionality. By comprehending the variegated lubrication systems, their merits, demerits, and imperative maintenance procedures, operators can foster seamless and reliable operation of their two-stroke engines across an extensive operational lifespan.

For a comprehensive repository of information regarding two-stroke engine lubrication systems and maintenance methodologies, use 2strokes.com