On the flight deck, visual clarity can impact decision-making, situational awareness, and mission safety. Pilots and crews depend on displays that stay visible and easy to read, even when sunlight is blazing through a cockpit window or when night falls and instruments rely solely on their own backlights. Achieving such reliable clarity under all conditions remains a challenge—a reflective display, often prized for its energy efficiency in sunlight, can struggle in low light, while transmissive panels may be washed out by ambient brightness. The need for optimum readability in every environment has made transflective display technology a pivotal advancement for cockpit instruments and navigation panels.

Reflective and transflective displays each bring unique strengths, but the ability of a transflective display to merge the best properties of both transmissive and reflective LCD technology makes it the preferred choice for aviation applications. This combination ensures that flight-critical data always remains readable, minimizing eye strain and reducing the risk of misinterpretation during crucial maneuvers.

What Is a Transflective Display?

A transflective display merges the core properties of transmissive and reflective display technologies. Standard reflective LCDs rely solely on ambient light, reflecting it to make graphics visible. Transmissive displays, on the other hand, use a backlight that is visible in low light but can be overwhelmed in bright sunlight.

Transflective displays utilize a specially engineered layer called a transflector, which both transmits the display’s internal backlight and reflects ambient light. During daylight, the display acts much like a reflective LCD, leveraging the sun or cabin lighting for perfect legibility without draining power. At night, it seamlessly transitions to transmissive mode, using its own light source to maintain clarity.

High Visibility in Varying Light Conditions

Cockpit environments pose extreme contrast in lighting conditions—direct sun during daytime flights, variable shadows at dawn or dusk, and pitch-black nighttime missions. The key advantage of a transflective display lies in its adaptability to such conditions.

A high-quality transflective display ensures:

- Crisp images and data beneath intense sunlight, thanks to ambient light reflection similar to a reflective display.

- Brightness and clarity in dim environments without washing out color or image detail.

- Smooth transitions between lighting extremes without sudden glare, distortion, or the loss of critical information that can befall solely transmissive or reflective LCDs.

As a result, pilots and crews can access crucial navigational data continuously—no matter how the external light changes throughout a mission.

Energy Efficiency and Thermal Management

Cockpit and panel electronics demand strict efficiency—not only to maximize battery and operating life, but also to limit excess heat that can cause electronic drift or outright failure. Reflective display types are known for consuming minimal energy because they do not require a backlight in most scenarios.

Transflective displays inherit this efficiency, significantly reducing power draw in bright conditions by utilizing ambient light. This reduction in backlight use:

- Cuts energy consumption, extending mission range or ground operations without constant recharging.

- Lowers heat generated by the display, supporting better cabin thermal management and overall instrument reliability.

- Allows display designers to utilize simpler cooling solutions and lighter enclosures, which are critical for modern aerospace weight requirements.

Reliability in Rugged Flight Conditions

Cockpit instruments endure vibration, pressure changes, shocks, and wide temperature swings on every flight. Displays must maintain clear output and maintain their form under these pressures. Transflective display constructions often feature ruggedized sealing and optical treatments that enhance their resilience:

- LCD layers are less prone to delamination or air gap failures due to their construction.

- Reflective and transflective mechanisms do not rely solely on fragile backlighting systems.

- Enhanced moisture and temperature resistance can be engineered into the transflective LCD design, especially when sourced from experienced providers such as E3 Displays.

These features safeguard against screen fogging, discoloration, or outright malfunction—protecting mission success and crew safety.

Integration in Modern Cockpit Systems

Modern avionics trend toward integrating more digital displays—moving away from analog dials to multi-function panels where data is centralized, context-based, and interactive. Transflective display designs can be produced in custom shapes, resolutions, and input configurations, supporting quick drop-in integration for both full retrofits and new builds.

Owing to their dual-mode operation, transflective displays:

- Harmonize with variable backlighting schemes, including night vision compatibility.

- Fit within tight panel spaces without the bulk of large cooling or lighting assemblies.

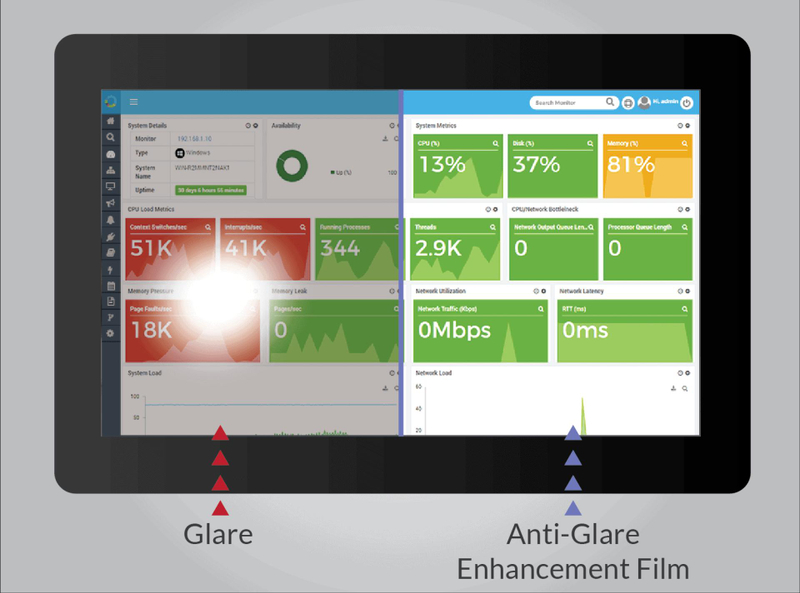

- Can be optically bonded or laminated with anti-reflective coatings to further boost readability and durability.

This flexibility speeds up prototyping, compliance testing, and production, resulting in lower integration costs and quicker deployment for original equipment manufacturers (OEMs).

Why Transflective Displays Improve Mission Safety

In aviation, safety is paramount. Instrument misreads, even momentary, can have serious consequences. Transflective display panels greatly diminish the risk of misinterpretation:

- Always-on visibility allows precise monitoring of engine metrics, flight data, navigational cues, and warning messages.

- The reduction in glare and minimized color washout means less pilot fatigue over long stretches.

- Power efficiency ensures the display remains operational during backup or emergency electrical usage.

Unlike purely reflective LCD options that can struggle during nighttime operations or transmissive displays that can fade in direct sunlight, transflective displays guarantee real-time awareness under all cockpit scenarios.

How E3 Displays Supports Aerospace OEMs with Transflective Solutions

E3 Displays specializes in designing and manufacturing transflective LCDs engineered specifically for aeronautical and high-reliability markets. Combining advanced transflective technology with decades of engineering experience, E3 Displays offers:

- Custom and standard sizes for seamless retrofit or next-gen applications.

- Ruggedized optical bonding, sealing, and anti-glare treatments for maximum visibility and reliability.

- Flexible production for prototype through to long-term supply programs, supporting aerospace product lifecycles.

- Deep collaboration with OEMs to customize performance in compliance with industry standards and regulatory environments.

With a focus on quality, durability, and lifecycle management, E3 Displays enables cockpit systems to stay ahead of operational challenges while remaining compliant and mission-ready.

A Smart Choice for Modern Avionics

Transflective display technology represents a convergence of best-in-class visibility, power efficiency, and durability—qualities particularly vital where safety, reliability, and operational clarity are non-negotiable. The hybrid functionality of a transflective LCD ensures optimal performance day or night in shifting conditions that define aviation.

A reflective display alone can’t offer the same balance, nor can a solely transmissive panel reach the same power-saving benchmarks under sunlit conditions. For aerospace OEMs, choosing transflective displays—engineered and supplied by trusted brands like E3 Displays—sets new standards in cockpit and navigation panel performance.

Contact E3 Displays to explore how transflective display technology can revolutionize cockpit designs, enhance clarity across all flight conditions, and enhance mission safety.