Traction gas springs, also known as traction struts or gas-filled supports, are mechanical devices that harness the power of compressed gas to provide controlled linear motion. These springs find extensive applications in various industries, ranging from automotive engineering to furniture design. This article delves into the principles, working mechanisms, applications, advantages, and considerations associated with traction gas springs.

Principles of Traction Gas Springs

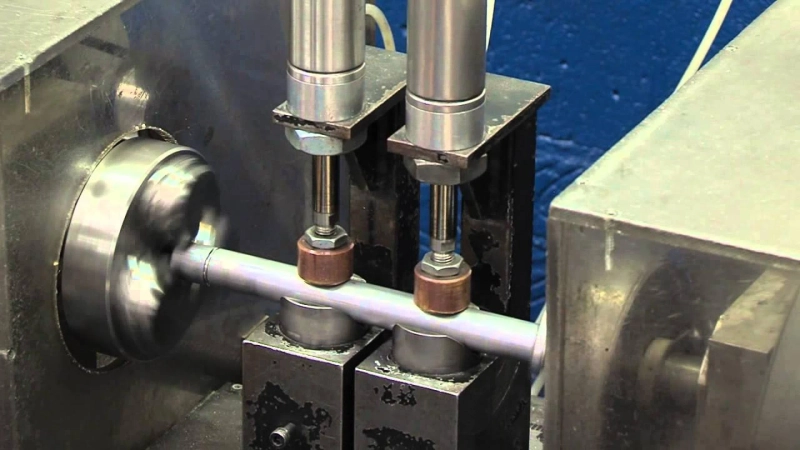

Traction gas springs operate on the basic principle of utilizing compressed gas to generate force, thereby enabling controlled linear motion. These springs consist of a gas-filled cylinder, a piston, and a rod. The gas within the cylinder is typically nitrogen, which is non-reactive and safe for most applications. As the gas is compressed, it creates a force that pushes against the piston, which in turn extends or retracts the rod attached to it.

Working Mechanism

The working mechanism of a traction gas spring involves a delicate balance between gas pressure, piston area, and the mechanical properties of the spring components. When the rod is pulled, the gas pressure in the cylinder increases, creating a force that resists the motion and seeks to return the rod to its initial position. Conversely, pushing the rod compresses the gas, generating a force that aids in extending the rod.

To ensure smooth and controlled motion, manufacturers carefully engineer the gas spring\'s components, including the piston seal, gas volume, and rod diameter. These factors influence the spring\'s force characteristics, damping properties, and overall performance.

Applications of Traction Gas Springs

Traction gas springs are utilized in a wide array of industries and applications due to their versatility and reliability. Some notable applications include:

Automotive Industry: Traction gas springs are used in vehicle hoods, trunks, and tailgates. They provide smooth and controlled motion, enhancing user experience and safety.

Furniture Design: Gas springs find application in adjustable chairs, beds, and tables, enabling ergonomic adjustments and enhancing user comfort.

Medical Equipment: Hospital beds, examination tables, and medical chairs often incorporate traction gas springs to facilitate height adjustment and patient positioning.

Aerospace: Aircraft seating, cabin components, and storage compartments utilize these springs to enable compact and controlled movement.

Industrial Machinery: Traction gas springs are employed in machinery access panels, conveyor systems, and ergonomic workstations to optimize ease of use and safety.

Marine Industry: Boat hatches, storage compartments, and cabin elements leverage gas springs to ensure controlled opening and closing.

Agricultural Equipment: Tractors, combine harvesters, and agricultural machinery incorporate gas springs to enhance convenience during maintenance and operation.

Advantages of Traction Gas Springs

Traction gas springs offer several advantages over traditional mechanical springs and hydraulic systems:

Compact Design: Gas springs have a compact form factor, making them ideal for applications with limited space.

Smooth Motion: These springs provide smooth and controlled linear motion, reducing wear and tear on components.

Adjustability: Gas springs allow for adjustable force and damping characteristics, making them versatile for various load and motion requirements.

Maintenance-Free: Unlike hydraulic systems, gas springs are virtually maintenance-free, reducing downtime and operational costs.

Safety: Traction gas springs incorporate built-in safety features, such as overload protection and damping, enhancing user safety.

Considerations and Maintenance

While traction gas springs offer numerous benefits, there are some considerations to keep in mind:

Temperature Sensitivity: Gas pressure can be affected by temperature changes, potentially altering the spring\'s performance. Selecting appropriate materials and designing for temperature variations is essential.

End-of-Life Behavior: Traction gas springs gradually lose gas over time, affecting their performance. Regular inspections and replacements are necessary to ensure consistent operation.

Mounting and Alignment: Proper mounting and alignment are crucial for optimal performance and longevity. Incorrect installation can lead to premature wear and reduced efficiency.

Environment and Contaminants: Harsh environments or exposure to contaminants can impact the gas spring\'s sealing and overall function. Protective measures may be required.

Conclusion

Traction gas springs have revolutionized the way linear motion is harnessed in various industries. Their compact design, smooth motion, adjustability, and safety features make them a valuable choice for applications ranging from automotive engineering to furniture design. By understanding the principles, working mechanisms, applications, advantages, and considerations associated with traction gas springs, engineers and designers can make informed decisions when incorporating these innovative devices into their projects, ultimately enhancing user experience and product performance.