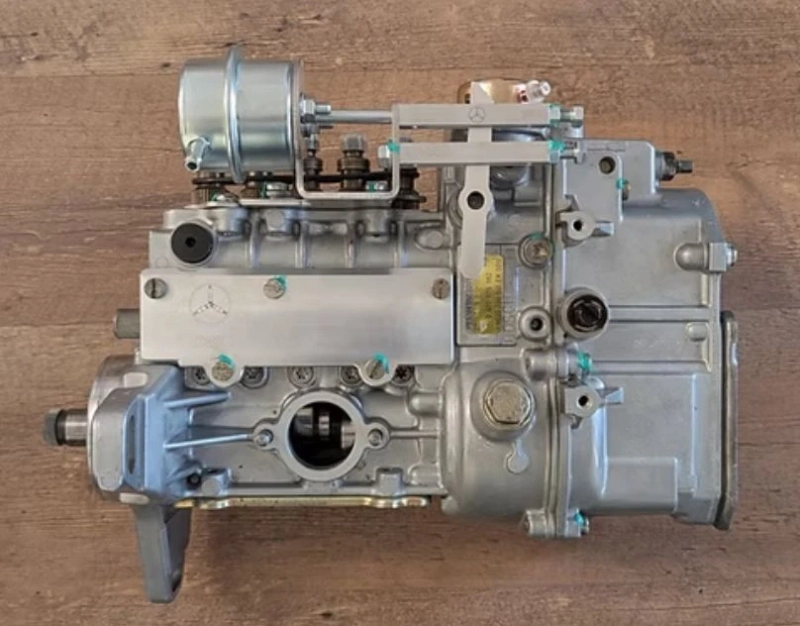

The heart of your diesel engine is the Performance 6 Cylinder (OM603 & OM606) Mechanical Injection Pump, which is responsible for delivering the right and precise amount of diesel to your engine for optimal performance and efficiency. If you own a vintage Mercedes-Benz or a modernized build, proper service to your mechanical injection pump is an essential key for the longevity and reliability of the wagon, and for consistent power production. In this article, we are going to cover the best practices for keeping you OM606 & OM603 mechanical pump running at its best.

1. Inspecting Fuel Lines and Connections Regularly

One of the first general maintenance practices for your OM603 & OM606 mechanical injection pump is to check the fuel lines and connections. Leaks or cracks in connections or lines could decrease fuel pressure, which would cause performance irregularity, and possibly damage the pump over time. Check all fittings for tightness and check them for corrosion. If lines or clamps look worn, consider replacing them, because it can save you from costly repairs, and keep your engine running smoother.

2. Use Quality Diesel Fuel

The quality of your fuel will directly affect the performance and longevity of your mechanical injection pump. Always buy clean and high performance grade diesel fuel. Always remember that poor quality fuel can create carbon build-up and or - contamination. A contaminated fuel supply can clog your injector and strain your pump and lead to decreased high performance and pump failure down the line. Sometimes adding a reputable fuel additive will help keep the injectors and pump clean, while keeping performance high.

3. Regularly Change Fuel Filters

Changing your fuel filters regularly is very important for the life of your Performance 6 Cylinder (OM606 & OM603) Mechanical Injection Pump. The fuel filters are there to protect your pump from dirt, debris, and water that can cause a lot of damage if they enter the pump. Regular replacement, according to the recommendations provided by the filter manufacturer, guarantees a proper flow of fuel to the pump. This is a basic job that may seem trivial, but neglecting it will lead to loss of performance and, ultimately, expensive repairs to the pump.

4. Properly Time the Engine

The mechanical injection pump works accurately because it is timed properly and can deliver the fuel at precisely the right time. Over time, the timing may drift due to wear and/or adjustments not being accurately set, in which case you may experience rough idling, reduced power, or excessive smoke. Having the timing checked and set periodically will ensure your OM606 or OM603 engine runs at its optimal performance for fuel economy and pump life.

5. Ensure the Pump is Well Oiled

The engine oil lubricates the OM606 & OM603 mechanical injection pumps to some degree. It is critical to ensure the engine oil is at the proper level and changed at the designated intervals. Using the correct oil for the engine along with a high-quality oil will help reduce friction and ultimately wear internally in the injection pump and potentially prevent the pump from failing in the case of running low on oil.

6. Do Not Run Low on Fuel

Running a diesel engine with low levels of fuel can introduce air into the fuel lines which can lead to cavitation and erratic pump performance. Air in the system can cause hard starting, non-consistent fuel delivery, and internal damage. It is always important to ensure adequate fuel levels for optimal performance and to protect the mechanical injection pump.

7. Schedule Professional Inspections

Regardless of whether you conduct yourself the maintenance of your own Performance 6 Cylinder (OM606 & OM603) Mechanical Injection Pump, you should schedule a professional inspection once in a while. Trained professionals recognize small problems before they become large problems, can help you calibrate the pump accurately, and will be a good partner in how you can achieve the most efficiency from your pump.

Conclusion

To ensure reliability, fuel efficiency, and longevity out of your Performance 6 Cylinder (OM606 & OM603) Mechanical Injection Pump you need to perform regular maintenance. Regular inspections, good clean fuel, changing your filters, lubricating properly, timing properly, and scheduling professional inspections will contribute to the overall longevity if your pump and engine. By having regular maintenance as a standard practice, diesel enthusiasts will have smooth and powerful reliability from their OM606 or OM603 engines for years to come.