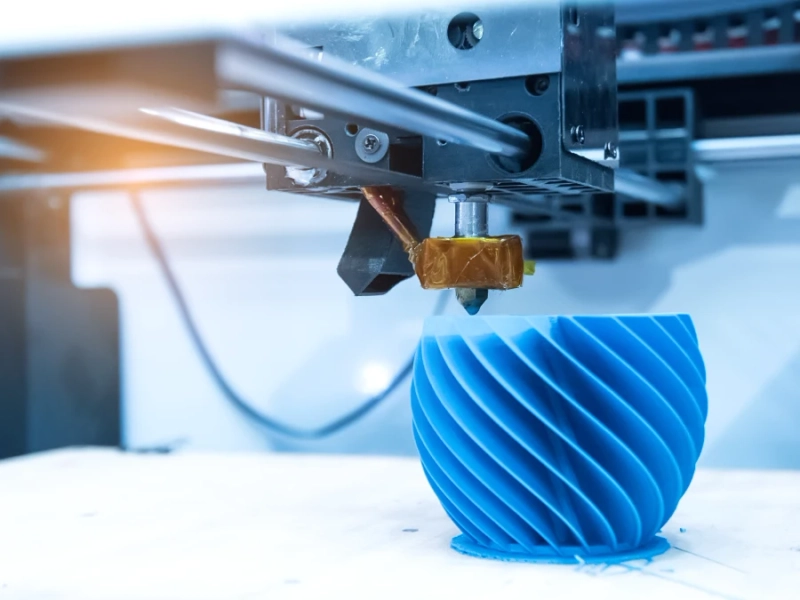

Additive manufacturing, commonly known as 3D printing, has made significant strides over the past decade. As we progress into 2025, its adoption across industries is no longer a novelty - it's a necessity. With advancements in materials, hardware, and software, additive manufacturing is revolutionizing how products are designed, developed, and delivered. Here are the top 10 applications of additive manufacturing in 2025 that are shaping the future of industry.

1. Aerospace Components

The aerospace sector continues to be one of the biggest adopters of additive manufacturing. In 2025, 3D printing is being used to create lightweight, high-performance components such as turbine blades, brackets, and housings. The ability to produce complex geometries while reducing material waste is especially valuable in this weight-sensitive industry.

2. Medical Implants and Prosthetics

Additive manufacturing is transforming healthcare by enabling patient-specific solutions. Customized implants, dental crowns, orthopedic supports, and prosthetics are now routinely printed to fit an individual’s anatomy. The technology allows for faster production and better patient outcomes.

3. Automotive Prototyping and Tooling

In the automotive industry, rapid prototyping is key to speeding up the design and development process. 3D printing helps engineers iterate quickly and test parts more efficiently. In 2025, additive manufacturing is also increasingly being used for custom tooling, fixtures, and even limited-run production parts for performance vehicles.

4. Consumer Goods Customization

The demand for personalized products is growing rapidly, and additive manufacturing is meeting this demand. From custom eyewear to personalized phone cases and footwear, 3D printing allows brands to offer unique products tailored to individual customer preferences.

5. Construction and Housing

The construction industry is embracing large-scale 3D printing for building homes and structures faster and more affordably. In 2025, printed homes are helping address housing shortages in several countries, offering sustainable solutions with minimal labor and waste.

6. Dental Applications

Dental labs are now using 3D printers for crowns, bridges, aligners, and dentures with unprecedented accuracy and speed. With the ability to scan, design, and produce same-day dental appliances, clinics are drastically improving the patient experience.

7. Education and Research

Universities and technical institutions are leveraging additive manufacturing to enhance learning and experimentation. Students and researchers can rapidly prototype mechanical systems, test new materials, and innovate in real-time—pushing the boundaries of what’s possible in various scientific fields.

8. Fashion and Jewelry Design

Additive manufacturing is empowering designers in fashion and jewelry with freedom to explore intricate, previously unproducible patterns. From high-end wearable art to mass-customized accessories, 3D printing is redefining aesthetics and production methods.

9. Defense and Military

In defense, 3D printing is being used for on-demand manufacturing of mission-critical parts in the field. This reduces dependency on long supply chains and ensures soldiers have access to spare parts, tools, and custom gear whenever needed.

10. Food Production

Yes, even food is being 3D printed. In 2025, additive manufacturing is making waves in culinary innovation—allowing for artistic presentations, controlled nutrient portions, and even personalized meals for people with dietary restrictions. This technology is also being explored in space missions for its efficiency and convenience.

Conclusion

Additive manufacturing in 2025 is no longer confined to prototyping—it is actively reshaping production models across industries. Its applications are driving innovation, sustainability, and customization like never before. As the technology continues to mature, businesses that embrace it stand to gain a significant competitive edge.