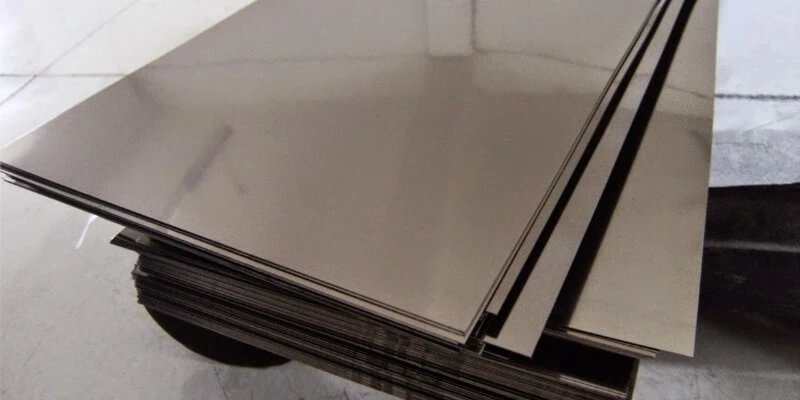

Titanium Grade 5 Sheet Advantages and Applications

Titanium Grade 5 is an alloyed titanium that is an alpha-beta alloy. Titanium Grade 5 is also known as Ti 6Al-4V since it is ...

Titanium Grade 5 is an alloyed titanium that is an alpha-beta alloy. Titanium Grade 5 is also known as Ti 6Al-4V since it is ...