You have likely heard that DC Probe Cards can make your testing process more efficient, but are you sure that you\'ve understood all the complexities? If you don\'t, you\'ll need to brush up on your knowledge before you can begin to improve your DC Probe Card testing processes.

Alignment test

There is a need for a system and method for aligning probe devices with wafer test pads. This may include a multi-step approach or a single step, as the case may be. A combination of optical and mechanical techniques are used to align a device such as a wafer test probe.

For example, a mask standard is used to simulate the tips of a test probe. The corresponding P/T data can be used to evaluate the repeatability of the position of the test probe. Similarly, a light box is used to measure coplanarity. Alternatively, a simple regression model may be used to calculate the magnitude of the most relevant P/T measures.

In a more conventional approach, a probe card is placed in a wafer prober and the device under test is aligned. This is accomplished through a series of steps, a few of which are outlined below.

Alignment data is repeatable

It\'s a fact that good alignment is not all that easy to come by. This is especially true of the optical axes. The trick is to come up with a method that is foolproof. One solution is to use the newest generation of telescopic sleds that are built with a gizmo. Fortunately, the best ones can be purchased with a little digging.

For a given axes of measurement, there is a sweet spot between the + 10 micron and the aforementioned +-4.6 microns. A few experiments in this ballpark were aplenty. However, the optimal balance between the two is still a work of art in the making. Regardless of the aforementioned limitations, a little experimentation yielded some interesting results. Among the findings was a fine-tuned version of the aforementioned sled that is capable of achieving a ten-micron femtosecond swivel-free femtosecond swivel-free accuracy.

Alignment data is affected by the number of DUTs that can be tested in parallel

A probe card is a device used in wafer testing. The DC Probe Cards provides an electromechanical interface between the tester and the DUT. It also supports repeated running of a test program on each DUT.

The number of DUTs tested in parallel has a direct impact on the efficiency of a probe card. If the number of DUTs is large, it can take an inordinate amount of time to switch from one DUT to the next. Therefore, a test cell must support a continuous, repetitive cycle of running a test program on each DUT.

In addition, the alignment of a DC Probe Cards with the pads on the wafer can result in damage to the wafer. This is why it is important to have good intermetallic contact.

Probe card efficiency is affected by the number of DUTs that can be tested in parallel

As the need for parallelism increases in semiconductor design, manufacturers are constantly seeking cost-effective testing solutions. One approach involves increasing the number of devices that can be tested in parallel. Another involves developing innovative strategies to accommodate parallelism on existing testers.

In the past, a traditional epoxy-ring, tungsten-needle DC Probe Cards could only accommodate up to sixteen DUTs in parallel. But, the industry has taken advances in both technology and parallelism, resulting in a new probe card architecture that is capable of testing more than eight to 256 dies in parallel.

These innovations include impedance matching, driver sharing, and built-in self-test techniques. These strategies help to reduce the overall cost of testing, as well as increase the reliability and scalability of multi-DUT testing.

Manufacturers have also made improvements to the geometry of the probe tip. These changes are designed to minimize material adhesion to the tip. This reduces the risk of contaminating the tip with bumps on the wafer.

Safe area of a probe card

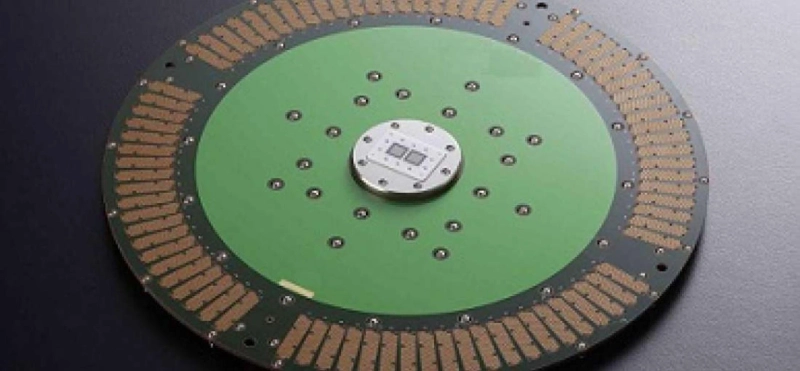

A probe card is a device that is used to inspect LSI chips. It includes a circuit board, a plurality of probes, and a supporter. The device is placed on a testing machine.

There are many types of DC Probe Cards available. They can range from MEMS to vertical. While a good probe card can last for years, a poor quality one may need to be replaced with a new one after a few hundred thousand test contacts.

One example is the cantilever beam probe card. Cantilever-beam technology involves a tungsten needle that is inserted into the PCB. Another option is a cantilever ring. Both are produced with the same techniques.

There are several factors that determine the efficiency of a probe card. For instance, a good one can be two times less expensive than a switch card. Also, the number of DUTs being tested in parallel has a big impact.

0