The rise of counterfeited products is rising, especially after the pandemic. The pharmaceutical industry is facing massive problems with the increased supply of fake medicines. The World Health Organization (WHO) computes that 1 in 10 medical products in low and middle-income nations is falsified. It’s a concerning matter that should be tackled as soon as possible. The serialization is necessary for the products that are at the target of the counterfeiters. It gives the power to the users to track them in the supply chain.

Product serialization is a powerful digital solution where a unique serial number is allotted to each product to give it a distinct identity. As a result, the brands and consumers can track and trace products wherever they lie in the processes. This digital solution has the capability to meet regulatory compliance mandates. Pharmaceutical is the only industry where serialization can be completely applied. But the companies still need to explore how these capabilities can improve supply chain planning, operations, and increase sales & marketing effectiveness. Let’s understand how it works:

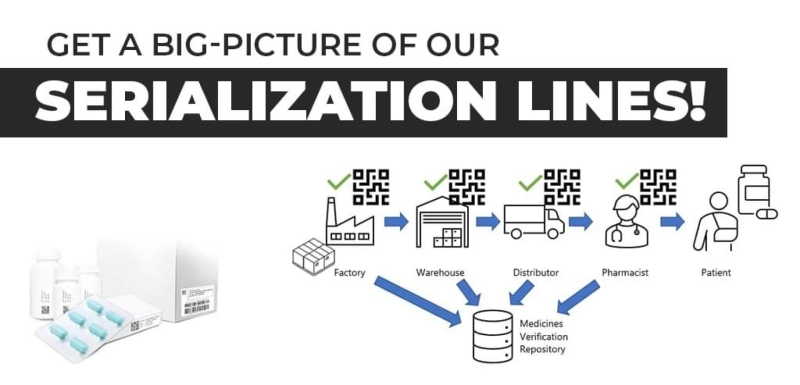

How does product serialization work?

The manufacturer can serialize every product with a serial number registered in an electronic data system. The powerful technology will immediately send a notification if there is any discrepancy in the supply chain mechanism or the counterfeiter tries to replace the original product with a fake one. When the consumer receives the product, the seller will receive an update.

To fight proactively against counterfeiting practices, companies need to adopt this powerful and technically advanced solution fast.

Drive business success with serialization

Protecting the products from counterfeiters is not the only solution that serialization offers. There’s much more to it. Businesses are looking forward to this digital solution because it provides:

- Inventory optimization

Pharmaceutical companies can increase their return on investment (ROI) by maintaining the reliability of the supply chain mechanisms. Product serialization just offers this by facilitating collaboration and improving the supply chain planning. It increases the agility and responsiveness of the stakeholders and optimizes inventory levels.

- Monitors the supply chain operations

Companies can achieve a competitive advantage by increasing the supply chain visibility. To make it happen, they need to focus on key performance indicators (KPIs). Product serialization captures and extracts transaction events, provides real-time data, ensures event management feedback, facilitates support monitoring, offers performance-driven supply chains, and allows real-time decision-making. It enables companies to monitor underlying business processes, leverage process improvement opportunities, and ultimately enhance product delivery that drives business success.

- Allows businesses to handle logistics issues

Processing returns, expirations, and product recall cost the pharmaceutical industry around $2 billion in a year. Companies need to work on this part to save their product recall costs. With this digital solution, they can fill these gaps by redesigning the logistics process. Tracking and tracing allow the brands to handle the return and recall of the products. The supply chain partners can verify the product while initiating returns. Serialized products assure the manufacturers about their authenticity at every step. They can spot the conduct of illegal activities in the return/recall process right from the start.

Prioritize product serialization

Pharmaceutical industries will benefit in innumerable ways after incorporating product serialization in their processes. It’s high time that brands should prioritize this digital solution to ensure authentic products. LetsVeriFy product serialization and track & trace solutions will take your brand authenticity to the next level!

0