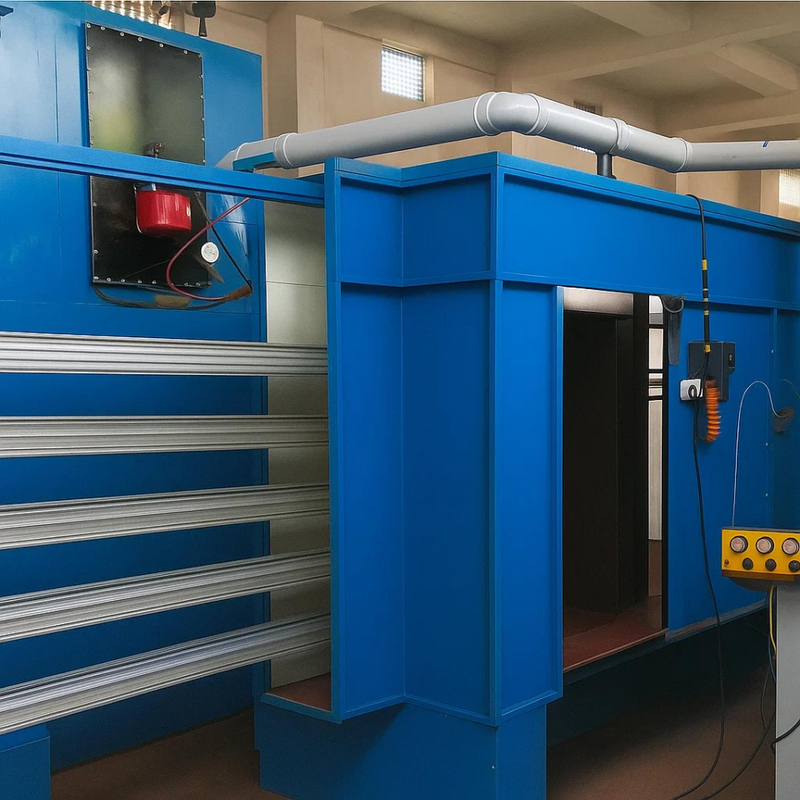

Aluminum Extrusions Powder Coating Plant

Aluminum extrusions are widely used in industries like automotive, construction, furniture, and electronics because of their lightweight, strength, and versatility. However, to enhance their durability and aesthetic appeal, a finishing process is essential. Powder coating is one of the most advanced and eco-friendly finishing methods available today. A dedicated aluminum extrusions powder coating plant ensures a superior, consistent, and long-lasting finish, meeting both functional and decorative needs.

What is Powder Coating?

Powder coating is a dry finishing process in which electrostatically charged powder particles are sprayed onto aluminum extrusions. The coated parts are then cured in an oven, where the powder melts and forms a smooth, hard coating. This method is widely preferred over traditional liquid painting due to its environmental friendliness, efficiency, and superior finish.

Key Benefits of Powder Coating Aluminum Extrusions

1. Exceptional Durability

Powder coating provides a thick, hard finish that protects aluminum extrusions from scratches, chipping, corrosion, and UV damage. This extends the product’s lifespan, making it ideal for both indoor and outdoor applications.

2. Enhanced Aesthetic Appeal

Powder coating offers a wide range of colors, finishes, and textures, allowing manufacturers to meet diverse design requirements. It delivers a uniform and high-quality appearance that does not run, drip, or sag, unlike traditional wet paint.

3. Eco-Friendly Solution

Powder coating produces minimal volatile organic compounds (VOCs) and overspray waste, making it a sustainable choice. Excess powder can often be recycled, reducing environmental impact and operational costs.

4. Cost-Effective and Efficient

Powder coating plants are designed for efficient material usage and high throughput. The process reduces rework and wastage while offering lower maintenance costs over time. Moreover, the one-coat application reduces labor time and improves productivity.

5. Superior Corrosion Resistance

Aluminum extrusions coated with powder are more resistant to moisture, chemicals, and extreme weather conditions. This makes them highly suitable for architectural, automotive, and industrial applications.

6. Consistent and Uniform Finish

An advanced powder coating plant ensures precise control over coating thickness and coverage, eliminating issues like uneven layers or pinholes. This enhances the overall quality and reliability of the finished products.

7. Quick Turnaround Time

Powder coating cures faster than conventional liquid paints, allowing for faster production cycles. This helps manufacturers meet tight deadlines without compromising on quality.

Why Choose a Dedicated Powder Coating Plant?

A specialized aluminum extrusions powder coating plant integrates advanced pretreatment, powder application, and curing systems to deliver high-quality finishes. The benefits include:

- Automation and Precision: Consistent results through automated systems.

- Energy Efficiency: Modern plants consume less energy, reducing operational costs.

- Scalability: Capable of handling small batches or large-scale production runs.

- Quality Assurance: Built-in inspection and testing ensure superior results.

Conclusion

You can invest in aluminum extrusions powder coating plant at GBM Industries. We’ve spent over 30 years providing our customers with start-to-finish powder coating services and are always looking for innovative ways to improve our processes even further.

Contact us to learn more about our powder coating services today!