SUBLIMATION ADVANTAGES – DISADVANTAGES – FUNCTIONALITY

In the following we provide you with extensive information about this type of finishing with our sublimation expert Mr. Gerd Müller.

WHAT IS SUBLIMATION?

Sublimation is an exciting printing process in which the colors are transferred directly into the textile using a special sublimation ink.

This is done through pressure and heat. Since the desired motif is printed in advance on a carrier paper, sublimation is to be assigned to transfer printing.

WHAT ARE THE ADVANTAGES OF SUBLIMATION?

Sublimation printing offers breathability and very high durability.

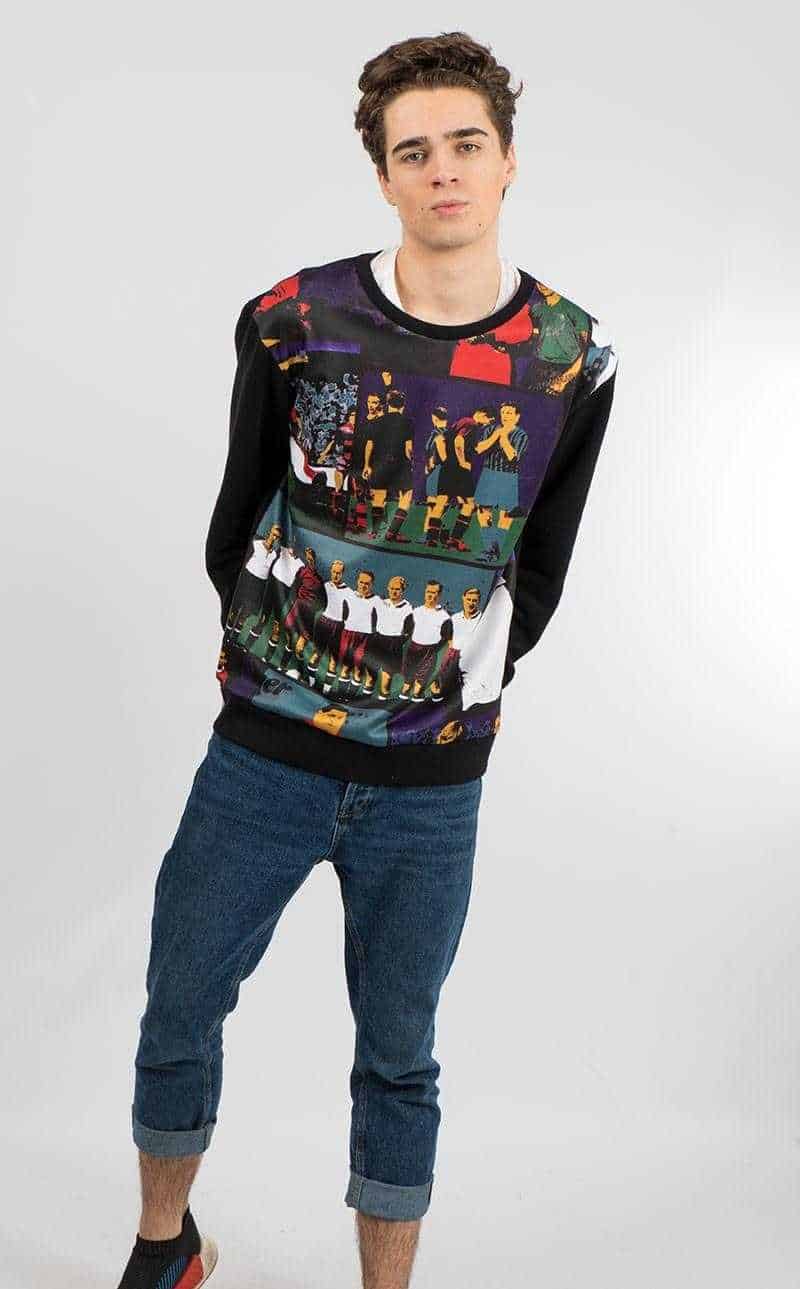

The already mentioned advantage of breathability is particularly important for sportswear, which is why sublimation printing is often used in this area. In addition to the wearing comfort, the absolute durability of the sublimation printed textiles should be mentioned. The high quality of the colors remains even after a very long time and delivers a photo-realistic result even with high-resolution motifs.

ARE THERE DISADVANTAGES OF SUBLIMATION PRINTING?

The textile must be made of synthetic fibers for sublimation printer in Pakistan, otherwise the color may differ from the original.

Sublimation is resource-saving and undoubtedly delivers a very great result. One restriction, however, is that the textile must be made of synthetic fibers. The lower the synthetic fiber content, the more the colors can deviate from the original.

HOW DOES THIS PRINTING TECHNOLOGY WORK?

With the help of digital printing and screen printing, carrier papers are created that are printed with special sublimation inks. The textile is then clamped in the sublimation printer and the colors are evaporated into the textile.

In order to create so-called carrier paper for the motif, we first select a suitable type of printing, e.g. digital printing or screen printing – most types of printing are possible here. We are currently producing motifs up to a size of 100 x 70 cm. The ink used is a special sublimation tine and represents the core of the sublimation. The textile to be printed is stretched absolutely wrinkle-free in our sublimation printer and evaporated under high pressure at approx. 180 ° for a few seconds. The colors change their physical state from solid to gaseous and back to solid. The evaporation prints directly into the textile and not just on the surface, which results in many advantages such as breathability.

WHEN DO I USE SUBLIMATION PRINTING?

Only textiles that are largely or entirely made of synthetic fibers (e.g. polyester) are suitable for sublimation printing.

Sublimation is only possible on textiles that consist entirely or to a very high degree of synthetic fibers. We recommend white textiles made of 100% polyester in order to achieve the best possible result with extremely high-resolution motifs. We have no restrictions with regard to the recommended quantities, we can meet any demand!

WHICH MOTIVES ARE CORRECTLY VALID BY SUBLIMATION PRINTING?

High-resolution images are best.

There are no limits to creativity, but particularly high-resolution images deliver first-class definition and fine colors. For motifs with many line colors, however, sublimation is not always recommended, as we can only work with an accuracy of approx. 90%. Basically, however, sublimation printing delivers exactly the desired quality and resolution, which was specified by the original file of the motif.

0

0