Metal finishing is one of those trades most people don’t think about until they need it, but once you start working on a restoration project, automotive upgrade, or custom metal job, you quickly realise how important it is. A clean, polished, and well-finished piece of metal can completely transform the look of a vehicle, a home feature, or even machinery. It’s not just about shine it’s about durability, protection, and quality workmanship.

Across Australia, metal polishing and chrome plating have played a big role in automotive culture, fabrication, construction, and even interior design. This guide breaks down what these services include, why they matter, and how to choose the right team for your next project.

Why Metal Finishing Matters

A good metal finish goes far beyond making something look pretty. High-quality polishing and chrome coatings protect metal surfaces from rust, corrosion, scratches, and wear. They also extend the lifespan of the item and make maintenance easier.

Metal finishing is commonly used for:

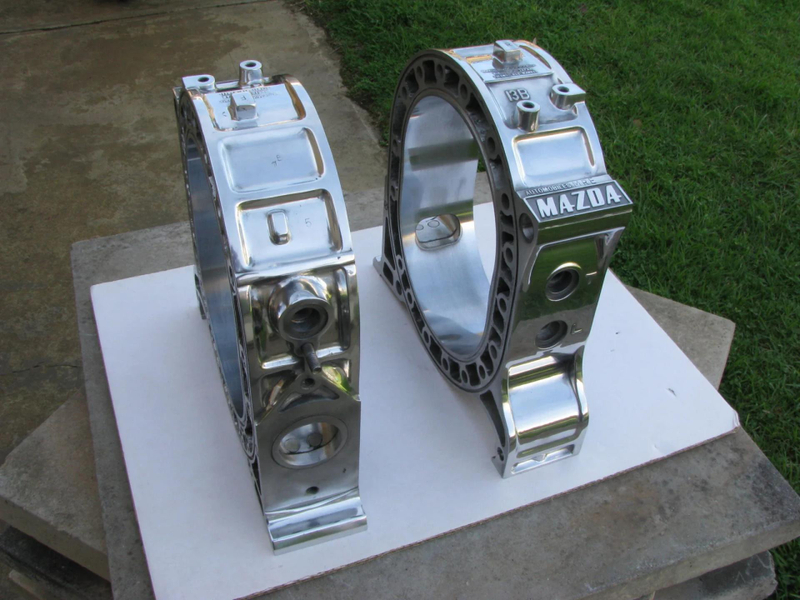

- Car parts and motorbike components

- Boat fittings and marine hardware

- Home fixtures like handles, trims, and frames

- Industrial machinery components

- Custom fabrication and restorations

Whether you’re reviving something old or finishing a brand-new piece, the right specialist will help you achieve a long-lasting result.

Understanding Chrome Plating in Australia

Chrome plating has been a popular choice for decades, especially in automotive projects. It gives metal a sleek, mirror-like surface while adding a strong protective layer.

Working with Chrome Platers in Adelaide means you’re partnering with professionals who understand the importance of preparation. Chrome plating isn’t as simple as dipping metal in a tank it requires cleaning, stripping, buffing, multiple coating layers, and careful polishing to achieve that flawless shine.

Chrome finishes are often used for:

- Bumper bars

- Custom trims

- Motorbike parts

- Boat accessories

- Decorative home features

Good chrome plating should have a smooth finish with no ripples, dark spots, or rough areas. When done right, it not only looks incredible but lasts for years.

What Metal Polishers Actually Do

Metal polishing is a skilled craft. It involves smoothing surfaces, removing marks, and creating a consistent finish that catches light beautifully. Some jobs require a mirror finish, while others need a softer sheen.

Teams like Metal Polishers in Adelaide handle everything from stainless steel and aluminium to brass and copper. The goal is to restore the metal to its best possible condition, whether that means removing scratches, fixing dullness, or preparing the surface for further coating.

Polishing can be done by hand or machine, depending on the size and complexity of the item. A good polisher understands the right pressure, equipment, and compounds needed for each material.

The Importance of Choosing the Right Metal Finishing Specialists

Not all workshops offer the same level of skill. Metal finishing is hands-on work and requires a lot of experience, especially when dealing with older or damaged pieces. A team with the right background can save you time, money, and frustration by doing the job correctly the first time.

Here’s what to look for when choosing a metal finishing professional:

- A clear portfolio with examples of past work

- Strong attention to detail

- Honest and reliable communication

- Quality tools and equipment

- Knowledge of how to handle different metal types

- Fair and transparent pricing

A great finisher treats every job big or small with the same level of care.

Why Adelaide Has a Strong Reputation for Metal Finishing

South Australia has always had a strong community of vehicle enthusiasts, builders, restorers, and fabricators. Because of that, the demand for polishing and chrome plating has grown steadily over the years.

Skilled workshops, such as Abel Metal Polishing in Adelaide, have built strong reputations for their craftsmanship and consistency. These local specialists understand the needs of car restorers, industrial clients, and homeowners who want quality work done with precision.

Choosing a local workshop also means quicker turnaround times, easier communication, and the chance to see examples of their work in person.

How to Prepare Your Metal Before Sending It In

You don’t have to do much, but a little preparation can help speed up the process:

- Give the item a quick clean to remove dirt and grease

- Take photos before dropping it off if you want to track progress

- Let the workshop know if there are any dents, cracks, or previous coatings

- Be clear about the finish you want mirror, satin, brushed, or chrome

The more information you provide, the easier it is for the specialists to deliver the exact result you're after.

Common Mistakes to Avoid with Metal Polishing and Chrome Plating

When working on metal projects, avoid these common errors:

- Choosing the cheapest quote without checking experience

- Trying to polish delicate parts with household tools

- Using harsh chemicals that damage metal

- Not discussing expectations beforehand

- Expecting a perfect finish on damaged or worn-down pieces without repairs

Quality metal finishing takes time, technique, and the right equipment and the results are worth it.

Final Thoughts

Whether it’s a classic car restoration, a motorbike upgrade, a custom fabrication, or simply giving old fittings a new life, quality metal finishing can completely transform the end result. Skilled workshops blend hands-on experience with the right tools to produce finishes that not only look impressive but also stand up to years of use.

With reliable and well-regarded teams like Abel Metal Polishing Adelaide, the region remains a go-to spot for top-tier metal restoration. The right specialists can help your pieces shine brighter, last longer, and truly reflect the craftsmanship behind your project.