Owning a manufacturing business means your output, revenue, and customer satisfaction all rely on having streamlined and efficient operations. This highlights the need for robust productivity in the manufacturing industry.

Improving productivity in manufacturing – who knew how crucial it can be? Though the fact is that if you want to make a mark in this industry and desire to emerge as a popular name then you need to pay attention to the level of productivity.

As we know time is money. The more production you can squeeze out in a period, the more money you make, right? Right.

But if you’ve been struggling with improving production or even if everything is going fine, there are several things you can do to increase throughput without sacrificing quality from removing obstacles to reorganizing the way you work. Let’s have a deep insight into these things.

Ways to Enhance Productivity in the Manufacturing Industry

Ways to Enhance Productivity in the Manufacturing Industry

It is crucial to pay attention to the existing workflow

Before improving anything, you need to have an analysis of the existing scenario. This will give you a fair idea about what you need to focus on and what all improvements are required. Certain things need to be considered, for instance,

The existing number of employees

Are the number of employees sufficient to carry the job. Are they skilled? If you don’t have the right number of people for any job or the right skilled people for a specific task then you need to work on it. You need to ensure that your HR team is working hard to employ the right set of people.

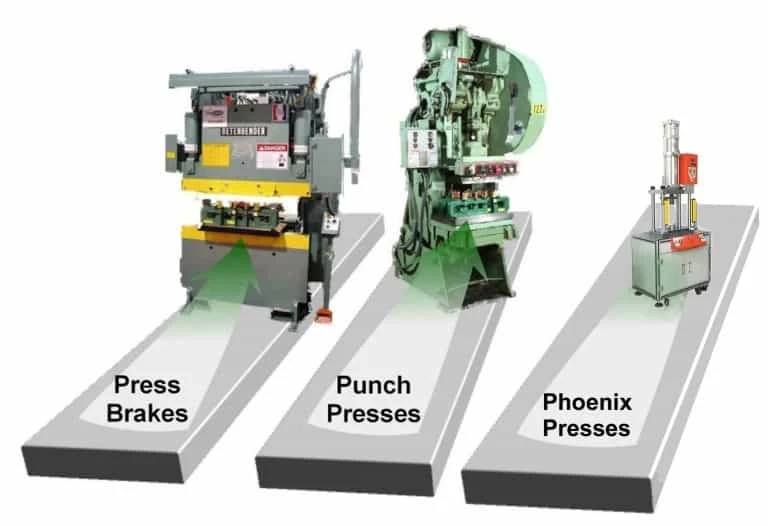

The right set of equipment and tools

It is crucial to ensure that you have the right set of high-quality tools and equipment to carry out the job of manufacturing. If the tools are not able to give the desired results then productivity will suffer. For instance, punching tools are used for hole-making in big machines and are known for their precision but if you buy an old tool then they will not serve their desired purpose and the final result will be affected.

Don’t brush maintenance job under the carpet

People often neglect the maintenance of tools but this is a huge mistake. Only maintained tools will yield highly precise and accurate results. Tools like punching tools, drilling tools, milling tools, etc., need regular maintenance to serve their purposes.

As prevention is better than cure, similarly, maintenance is better than repairing. Downtime for maintenance costs much less than downtime due to broken and worn equipment. Maintenance can be scheduled; breakage always comes at the worst possible time.

Educate and train your staff

If you have an educated and highly skilled staff then you’re the productivity of your manufacturing firm is bound to increase. It takes an army to run a manufacturing unity and you need to choose the right people to be a part of your army or else you will lose your clients to your rivals.

Employee education is also an excellent retention tactic; new employees take time to become proficient, causing a slowdown in production.

So, don’t limit training and education to equipment. Your manufacturing facility will run more smoothly if everyone understands your policies on workplace harassment and proper communications.

Final words

It takes a lot to run a manufacturing firm and built your trust among clients. The only thing that can help you sustain all this is smooth and massive productivity. The above-mentioned ways will help you in ensuring a high pace of productivity and your success in the industry.