Material protection has traditionally been a significant concern for consumers, but antibacterial-treated porous and nonporous products have become increasingly popular due to their additional function. Porous and nonporous antiviral-treated products have recently appeared on the market.

For nonporous products, ISO 22196 specifies a method for determining antibacterial activity. ISO 20743 describes the antibacterial activity measurement method on porous products (textiles). This document describes a method for testing nonporous products for antiviral activity. As a result, it has been written by ISO 22196 and 18184.

For use in ISO 22196, this document is designed to apply to nonporous materials.

ISO 21702 – Antiviral activity on nonporous surfaces such as plastics

Plastics and other nonporous surfaces are evaluated using ISO 21702 antimicrobial surface tests for their antiviral properties. Viruses that have come into contact with a plastic or similar material\'s treated surface will test using the ISO 21702 standard test method. Influenza a virus and Feline calicivirus are examples in ISO 21702 antiviral testing.

ISO 21702, one of the most frequently requested antiviral surface test methods, can be used to evaluate the antimicrobial activity of plastic and nonporous products that have been dealt with antivirals. Plastics treated with antimicrobial agents may meet test requirements, but they may not function as intended after being subjected to simulated environments. Antiviral plastics need to be subjected to scrutiny in various conditions, including UV exposure, humidity, and the use of release agents. Using ISO 21702 test or another antimicrobial test in conjunction with durability testing can provide valuable information on how a material will perform in its intended use environment.

Many customers will request a product\'s antimicrobial performance to be tested in conjunction with ISO 21702 testing to determine the product\'s ability to withstand environmental conditions. As a result of the test laboratory for Both Durability and antibacterial testing, the time and costs associated with developing a finished product can significantly lessen. Another benefit of quality control testing is that customers can be confident that their product performs optimally batch after batch, allowing them to provide consistently high-quality products.

WARNING: The handling and manipulation of potentially hazardous viruses and host cells necessitates a high level of technical competence and may be subject to current national legislation and regulations. Strict adherence to recommended sanitation standards, sterilization, and personal hygiene are required.

- Area of Study

Antiviral activity on plastics and other nonporous surfaces of antiviral-treated products can be measured using the methods outlined in this document. Some findings may not apply to other viruses.

- Definitions and explanations

- This document makes use of the terms and concepts listed below.

- For standardization, the ISO and IEC maintain the following terminological databases:

- Available at https://www.iso.org/obp, the ISO Online Browsing Platform

- It is possible to access the IEC Electromedical at http://www.electropedia.org/.

- Antiviral

Decreased infection risk due to lower product surface viral particle counts.

- Agent for the prevention of viral infection

Reduces the number of infectious viruses on product surfaces that can spread

- Ability to fight viruses

The disparity between the logarithm of the viral infectivity titer in products treated with and those not treated after virus inoculation and contact.

- A cytotoxic effect on cells

Virus-induced alteration or destruction of the cellular structure of the host. This test measures the amount of cytotoxic effect on cells.

- A virus\'s ability to infect

The volume of infectious viral particles per unit volume in suspension can be easily measured using this test.

- Plaque

Lysis was observed in the cell monolayer under a semisolid medium due to an infectious virus that infected and multiplied rapidly. The amount of Lysis was found using this test.

- Units of a plaque

PFU measures the infectious viral particle concentration per unit volume (ml).PFU can easily find out using this test.

- The examination of plaque

Series of diluting viruses (3.5 PFU) to determine the virus\'s infectivity. To determine the antiviral activity of treated plastic and nonporous products such as water-resistant textiles, paint, metal surfaces, and ceramic tiles, ISO 21702 is applied. A durability test in conjunction with the ISO 21702 provides valuable information about the sample material\'s antiviral performance in a real-world setting.

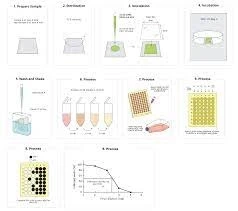

Protocol for conducting a test.

- Five-centimeter squares (cm) are traditionally used in triplicate. The inert control surface has nine yards and six on the test surface.

- Each test and control square receives 400 l of the virus. Liquid media using to remove the remaining virus after a standardized contact time.

- Indirectly, it can determine whether or not the virus survives on the test and control surfaces. This procedure has been completed to my satisfaction by examining mammalian host cells.

- Crystal violet staining identifies virus-infected (white) cells from uninfected ones.

- This test determines a surface\'s antiviral efficacy.

- Compared to a control sample, a lower R-value indicates that the virus concentration on the test sample has decreased.

- The sample tested must have an R-value of 2 or higher to demonstrate antiviral activity.

R-Value Interpretation

A reduction in infectious virus by 90% compared to the control sample is represented by R = 1 means reduced by 299 percent. When R setting to three, it is reduced by 99.9 percent. Over time, viruses degrade and cease to be active on any surface. It necessitates using an inert control to determine the R-value properly.

The R-value provides information on virus inactivation. The above method determines viral activity due to the possibility of varying lab conditions from day to day and batch to batch variability in the virus stock used.

Controls:

This section explains how the ISO 21702 test is carried out, along with the sample. Under laboratory conditions, this test measures cytotoxicity against cells grown in liquid media.

The sample is not treated:

The antiviral activity of many plastics and nonporous substances is inert against a wide range of viruses. Identifying the surface\'s sluggish antiviral activity and the compound coated on it is critical. It\'s done by simultaneously saturating the untreated surface with the virus as the test sample saturates the treated surface. The virus is incubated and then tested to see if the untreated surface has antiviral effects. Using this as a check, we can see if the compound\'s surface antiviral properties are accurate.

Tilting the syringe:

An issue with the virus supply could signify that the virus concentration was too low. It means that a direct virus supply is used to determine the experiment\'s initial virus concentration by directly infecting host cells with a dose of the virus.

As a result, it\'s possible to tell if the virus tested had an exceptionally high infectivity titer. Also included is information about the maximum virus concentration that is recoverable from testing.

The study of microbes

Researchers from the ETH Institute of Food, Nutrition, and Health founded Microbe Investigations, a spinoff company, in 2012 due to their work at the ETH.

During the two-week ISO 21702 testing period, use the following SARS CoV-2, Beta Coronavirus (OC-43), Human Coronavirus (229E), Influenza A (H1N1), and Influenza A (H3N2) strains: (ATCC VR-1679). A fast and straightforward booking process is available. It will be carried out the ISO 21702 testing in our lab and deliver the report on the date you specify.

0