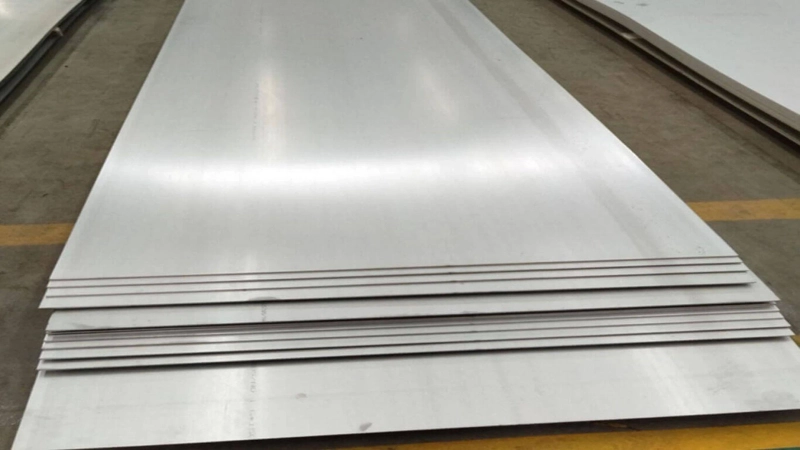

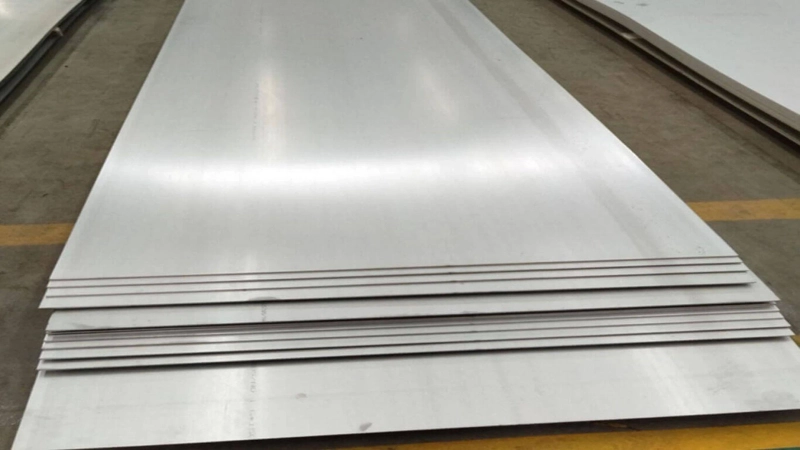

How To Use UNS N10276 Sheet To Your Advantage

Dinesh Tube India is the largest uns n10276 sheet stockist which is corrosion resistant, heat resistant, etc. & has many uses in many sectors

Dinesh Tube India is the largest uns n10276 sheet stockist which is corrosion resistant, heat resistant, etc. & has many uses in many sectors