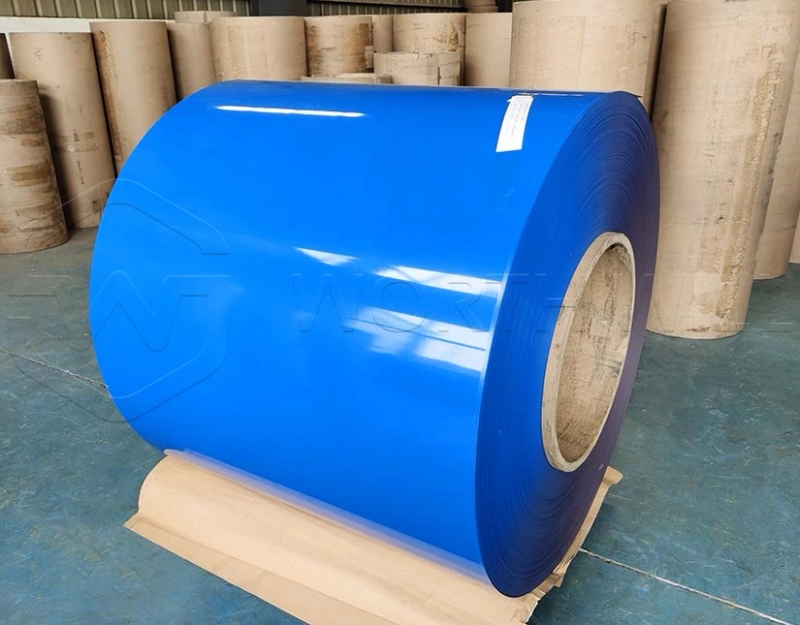

Pre-painted aluminum coils have become a popular choice for a wide range of applications due to their high durability, versatility, and aesthetic appeal. However, like any other construction material, improper handling and use of these coils can lead to serious accidents. That\'s why it\'s essential to take safety measures seriously when using pre-painted aluminum coils. Here are some tips on how to safely operate pre-painted aluminum coils.

1. Always wear protective gear

One of the critical safety measures to take when operating pre-painted aluminum coils is to wear the right protective gear. Depending on the task at hand, you may need to wear gloves, safety glasses, earplugs, boots, a protective suit, or a helmet. Protective gear shields you from potential hazards, such as sharp edges, flying debris, or fumes that can pose serious health risks.

2. Handle the coils with care

Pre-painted aluminum coils are delicate materials, and rough handling can cause damage to the surface, leading to scratches or dents. When moving the coils, use a forklift or a hand truck to avoid dragging them on the ground or bumping them against other objects. Similarly, avoid stacking the coils too high, as they may tip over, causing damage to the material or injury to workers.

3. Store the coils properly

Proper storage of pre-painted aluminum coils is crucial to preserve their quality and ensure worker safety. Keep the coils in a dry, cool, and well-ventilated area to prevent corrosion, warping, or discoloration. You can stack the coils vertically or horizontally, depending on the available space and the weight of the material. Additionally, label each coil with its weight, size, and other relevant information to avoid confusion during storage or transportation.

4. Install appropriate safety guards

If you use equipment such as slitting machines, shears, or press brakes, ensure that they have adequate safety guards to prevent accidents. Safety guards can stop the machine when a worker\'s hands or body parts come into contact with dangerous moving parts or blades. Moreover, ensure that the machines are appropriately maintained and inspected regularly to detect any signs of wear or malfunction.

5. Train workers on safety procedures

Safety training for workers is crucial to prevent accidents and minimize risks when working with pre-painted aluminum coils. Train workers on how to identify potential hazards, use protective gear correctly, handle and store the coils properly, and operate machinery safely. Additionally, create a safety plan and emergency response procedures in case of accidents, and practice them regularly to ensure that workers are ready to act in any situation.

In conclusion, pre-painted aluminum coils are versatile and durable materials that require careful handling and use to ensure worker safety and minimize accidents. Always wear protective gear, handle the coils with care, store them properly, install safety guards on machinery, and train workers on safety procedures. These measures will not only prevent accidents but also extend the life of the material, saving you time, money, and hassle in the long run.