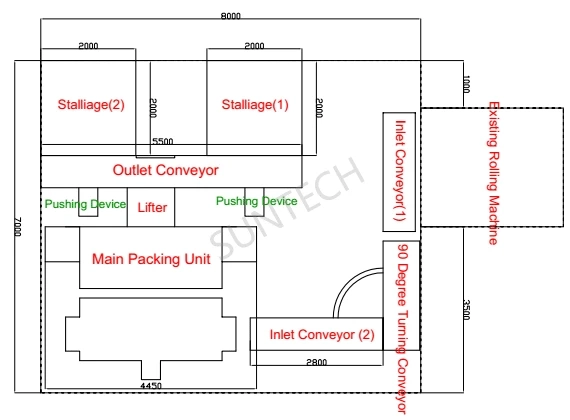

The operator places the fabric roll on the inlet conveyor; the fabric roll is then transported to the main packing machine, where the main width and side sealing are completed, and the vacuum packing is completed in the heat chamber. After vacuum packing, the turning conveyor transports the fabric roll to the storage table.

SUNTECH\'s basic inspection&packaging line consists of a fabric inspection machine, a fabric intake conveyor, a fabric main packing machine, a fabric output conveyor, a heat chamber, a 90-degree turning conveyor, and a storage stable (cloth trolley).

Effect of vacuum packing:

Why is SUNTECH\'S FABRIC ROLL INSPECTION&PACKING LINE SO POPULAR IN THE INTERNATIONAL MARKET?

1)This is a fully automated fabric roll wrapping machine that needs only one operator to operate, hence reducing labor costs.

2)With a packing speed of up to 7 rolls per minute, this automated fabric roll wrapping machine has a high packing efficiency. For example, the ST-ARPM-180I can pack around 5-7 rolls every minute, or approximately 2400-3360 rolls per eight hours.

3)Material cost savings compared to typical plastic bags, about 10% cost savings based on testing findings.

4)This automated fabric roll wrapping machine may be connected to an inspection machine for online inspection and packaging; under ideal conditions, one packing system can support up to ten fabric inspection machines simultaneously.

5)In comparison to European suppliers, our fabric inspection machine price and packaging machines are more affordable.

HOW TO SELECT AN APPROPRIATE FABRIC INSPECTION MACHINE FOR EACH CLIENT?

We offer a variety of fabric examination machines. As an established producer of textile machines, SUNTECH is able to propose the most appropriate inspection machine for each client, determining the kind of function required and the manufacturing process in which the machine will be used...

While some manufacturers of fabric inspection machine for sale only provide conventional models, we can create customized designs to fulfill specific client requirements.

The primary client requirement for knitted textiles is to regulate the fabric tensions and completely open the curled fabric edges. Typically, the entrance of the knitted fabric inspection machine has a dancing roller that ensures the fabric feeding or unwinding, inspecting, and rewinding speeds are matched.

The dancing roller will adjust the fabric tension by moving up and down. If the feeding, unwinding, and rewinding speeds are not synchronized, the potentiometer positioned on one side of the dancing roller will send a signal to the inverters located at the feeding and rewinding positions, and the inverters will modify the speed to match. Following the inspection table is a frequency controller that controls the speed of the inspection and rewinding positions. There is a single screen that displays the tension and a button for adjusting it. As a result, the operator may modify the tension amount using the button.

PVC coated textiles should not be overstretched to prevent damaging the plastic coating. Excessive stretching may result in the plastic layer losing its smooth texture and becoming striated, as well as losing part of its original sheen and perhaps tearing.

For PVC coated textiles, we have a particular design. To preserve the coated layer, the inspection machine is fitted with one aluminum scroll roller, which is lighter than a standard scroll roller. Additionally, the edge alignment station located at the entrance ensures that the fabric edges are properly aligned after rewinding. Cold slitting cutters for cloth edges or center slitting are offered for the customer\'s selection.

We are a manufacturer of fabric make-up machines, and we are well aware of the types of machines that are ideal for various factories, such as weaving mills, knitting mills, and dying&finishing units. SUNTECH will assist the client in selecting the most appropriate equipment to meet the need. In comparison to other fabric inspection machine manufacturers, we are confident in the quality of our product.

0