The cannabis industry has rapidly evolved from small-scale operations to large-scale production facilities requiring advanced solutions. Among the most significant advancements is the automated pre-roll infusion robot, which is revolutionizing how infused products are made. These intelligent systems provide precision, scalability, and speed—factors that are essential for cannabis companies aiming to compete in today’s saturated market.

What Is an Automated Pre-Roll Infusion Robot?

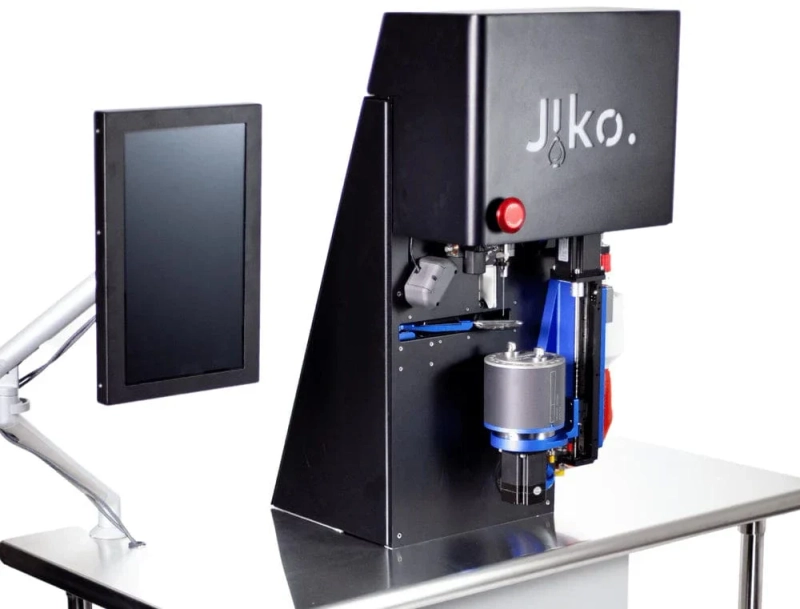

An automated pre-roll infusion robot is a specialized machine designed to inject cannabis concentrates directly into pre-rolled joints with precise dosing. This automation eliminates the need for manual application, significantly reducing labor and enhancing consistency. The result is a high-quality infused product that maintains potency, burn quality, and user satisfaction—batch after batch.

Transforming Production Efficiency

Before the introduction of automated systems, infusing pre-rolls was time-consuming, requiring skilled labor and attention to detail. With an automated robot, businesses can now infuse hundreds to thousands of pre-rolls per hour with pinpoint accuracy. This not only speeds up production but also ensures uniform distribution of concentrate across every unit—something human labor struggles to replicate at scale.

Sorting Robotics, a leader in cannabis automation, has engineered its infusion robots to maximize throughput without sacrificing quality. By automating what was once the most labor-intensive part of pre-roll manufacturing, cannabis processors can now scale faster and more cost-effectively.

Ensuring Dosage Consistency and Product Quality

Consistency in dosage is critical in the infused product market. Manual processes often lead to under- or over-dosing, which can harm both compliance and consumer trust. Automated pre-roll infusion robots are equipped with precision dosing systems that accurately measure and inject exact amounts of concentrate into each pre-roll.

These systems also maintain the structural integrity of the joint. Instead of soaking or coating, the infusion is internal and controlled—preserving the natural burn rate and appearance. Sorting Robotics has focused heavily on maintaining this balance in their engineering to ensure both functionality and product aesthetics.

Versatility Across Concentrate Types

Modern infusion robots are designed to handle a variety of cannabis concentrates—from distillates to more viscous forms like rosin and live resin. This versatility opens doors for cannabis brands to experiment with high-end products without changing equipment or production lines. Temperature control, viscosity management, and multi-profile compatibility are built into these machines to accommodate a wide range of formulations.

Sorting Robotics has developed models capable of adapting to different concentrate profiles, giving brands the flexibility to stay innovative and responsive to consumer trends while keeping operational complexity low.

Supporting Compliance and Reducing Operational Risk

Automation isn't just about speed—it’s also about control and traceability. Pre-roll infusion robots often include software that tracks infusion volumes, batch IDs, and processing data. This makes compliance reporting and internal audits significantly easier. Furthermore, by reducing human touchpoints, robots help lower the risk of contamination or inconsistencies.

For cannabis companies operating under strict state and national regulations, this kind of automation ensures that infused products consistently meet legal requirements—while also offering peace of mind during inspections.

Enhancing ROI Through Labor Reduction

Labor is one of the highest recurring costs in cannabis production. Manual infusion processes require not only time but also skilled workers who can ensure accuracy and quality. Replacing this with a robot significantly lowers labor dependency and reduces costs in the long term.

With an investment in automated systems like those from Sorting Robotics, cannabis producers experience improved margins, faster production cycles, and a much quicker return on investment. The automation pays off by enabling facilities to meet increasing demand without sacrificing quality or expanding the workforce.

Conclusion

The automated pre-roll infusion robot is more than just a tool—it’s a game-changer for cannabis brands seeking growth, consistency, and operational excellence. As consumer demand for infused products continues to rise, businesses that integrate robotic automation will be best positioned to lead the market.

By incorporating intelligent automation from companies like Sorting Robotics, cannabis producers can achieve the speed, quality, and innovation needed to stay competitive in an evolving industry.

FAQs

What is an automated pre-roll infusion robot?

An automated pre-roll infusion robot is a machine designed to inject cannabis concentrates directly into pre-rolled joints with high precision. It automates the infusion process, ensuring consistent dosing and faster production rates compared to manual methods.

How does an infusion robot improve cannabis production efficiency?

Infusion robots dramatically increase throughput by processing hundreds to thousands of pre-rolls per hour. They eliminate the need for manual labor, reduce errors, and allow for scalable production without sacrificing quality.

Can infusion robots handle different types of cannabis concentrates?

Yes, most automated infusion robots, including those from Sorting Robotics, are engineered to work with a variety of concentrates such as distillates, rosin, and live resin. They feature adjustable temperature and flow controls to accommodate different viscosities.

Are automated pre-roll infusion robots compliant with cannabis regulations?

Yes, these machines often include tracking and data-logging features that help producers maintain compliance with dosing regulations and product consistency standards. They also reduce human contact, helping meet hygiene and safety requirements.

What is the ROI for investing in an automated infusion robot?

The ROI is typically strong due to labor savings, higher production volumes, and better product consistency. Most cannabis companies recover the cost through increased efficiency and reduced operational costs within a short timeframe.