Introduction:

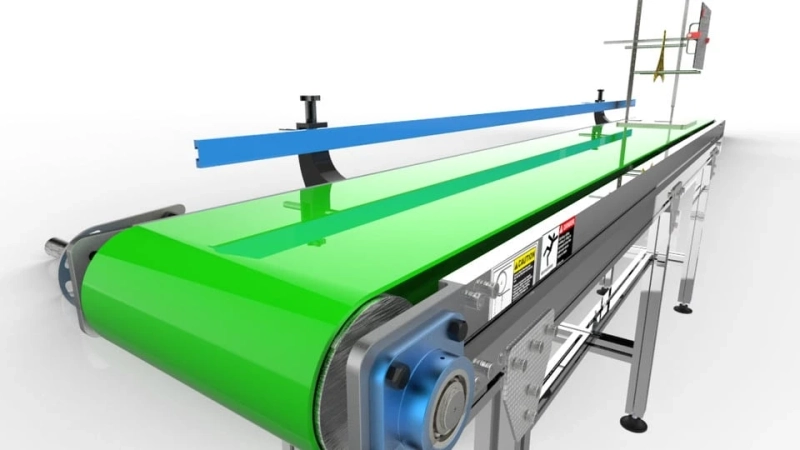

Conveyor belts play a crucial role in various industries, facilitating the smooth and efficient movement of materials. To ensure optimal performance and longevity of your conveyor belt, it is essential to follow a comprehensive guide. In this article, we will delve into the key strategies and best practices to get the most out of your conveyor belt, with a focus on the innovative solutions provided by TSGlobal.

Regular Maintenance:

Proactive maintenance is the cornerstone of maximizing the lifespan and efficiency of your conveyor belt. Implement a regular inspection routine to identify and address potential issues before they escalate. Check for wear and tear, misalignments, and any unusual noises during operation. TSGlobal emphasizes the importance of routine maintenance and provides comprehensive guidelines to help you keep your conveyor system in top-notch condition.

Proper Training for Operators:

Well-trained operators significantly contribute to the smooth operation of conveyor belt. Ensure that your staff is adequately trained on the proper usage, troubleshooting, and safety measures associated with the conveyor system. TSGlobal offers training programs tailored to the specific needs of their conveyor systems, enhancing operator competency and reducing the risk of operational errors.

Optimal Loading:

Efficient loading is critical for the performance and longevity of conveyor belts. Overloading can lead to accelerated wear and tear, while underloading may cause slippage and increased tension. TSGlobal\'s expert recommendations on load management ensure that your conveyor system operates at its optimal capacity, balancing throughput and longevity.

Environmental Considerations:

Conveyor belts are exposed to a variety of environmental factors, including temperature fluctuations, humidity, and abrasive materials. TSGlobal\'s conveyor belts are designed with durability in mind, but it\'s essential to consider the specific environmental conditions in your facility. Implement protective measures such as covers and climate control to shield the conveyor system from adverse effects, ensuring longevity and reliable performance.

Lubrication:

Proper lubrication is vital for reducing friction, minimizing wear, and preventing breakdowns in your conveyor system. TSGlobal provides specific guidelines on the appropriate lubricants and schedules for their conveyor belts. Follow these recommendations to maintain optimal performance and extend the life of your conveyor components.

Monitoring Systems:

Implementing a robust monitoring system is crucial for detecting issues in real-time and preventing costly downtime. TSGlobal integrates state-of-the-art monitoring technologies into their conveyor systems, allowing users to track performance metrics, identify potential problems, and receive timely alerts. Regularly review the data provided by these monitoring systems to proactively address any issues before they impact productivity.

Emergency Preparedness:

Despite meticulous maintenance and monitoring, unexpected issues can still arise. TSGlobal emphasizes the importance of having a comprehensive emergency response plan in place. Ensure that your team is well-versed in emergency procedures and that necessary tools and spare parts are readily available. This proactive approach minimizes downtime and contributes to the overall efficiency of your conveyor system.

Conclusion:

Getting the most out of your conveyor belt involves a combination of proactive maintenance, proper training, environmental considerations, and the implementation of advanced technologies. TSGlobal stands out as a leading provider of conveyor solutions, offering not only cutting-edge technology but also comprehensive support through training and maintenance guidelines. By following this guide and leveraging TSGlobal\'s expertise, you can ensure that your conveyor belt operates at peak efficiency, contributing to the success of your operations.