When we think about the backbone of modern infrastructure—skyscrapers, bridges, automobiles, or even household tools—one material stands out: steel. But behind every sturdy frame or finely crafted wire lies an intricate process that transforms raw minerals into industrial-grade strength and precision. The journey of industrial steel and wire is a fascinating one, marked by innovation, craftsmanship, and engineering excellence.

1. The Beginning: Extracting Raw Materials

Every piece of steel begins with nature. The journey starts deep underground, where iron ore is mined. This ore is the primary raw material for steel production and is extracted from mines around the world. Along with iron, other essential materials like coal (used to produce coke) and limestone are gathered.

Once the raw materials are ready, they’re transported to steel plants where the transformation begins. Here, nature’s elements meet human ingenuity to create one of the most versatile materials known to mankind.

2. Smelting and Refining: Turning Ore into Steel

The next step in the process involves refining these raw materials in massive blast furnaces. Inside these furnaces, iron ore, coke, and limestone are combined and subjected to extremely high temperatures—often over 1500°C. The coke burns to produce carbon monoxide, which reduces the iron ore to molten iron.

This molten iron, however, is not yet pure steel. To achieve the desired quality, impurities such as sulfur, silicon, and phosphorus are removed through a process known as basic oxygen steelmaking (BOS) or electric arc furnace (EAF) refining. Alloying elements such as chromium, nickel, and manganese may also be added to enhance specific properties like corrosion resistance, hardness, or flexibility.

The result is clean, high-quality steel—ready for shaping into countless industrial applications.

3. Casting: Giving Steel Its First Shape

Once refined, the molten steel is cast into solid forms. This is often done through a process known as continuous casting, where the liquid steel flows into a mold and gradually cools to form semi-finished shapes like slabs, billets, or blooms.

These shapes are the starting point for various end products. Slabs are typically rolled into sheets or plates, while billets and blooms are perfect for manufacturing wire rods, bars, and structural components.

At this stage, quality control becomes essential. Engineers test for consistency in composition, surface smoothness, and mechanical properties to ensure that every piece meets strict industry standards.

4. Rolling and Drawing: Shaping the Future

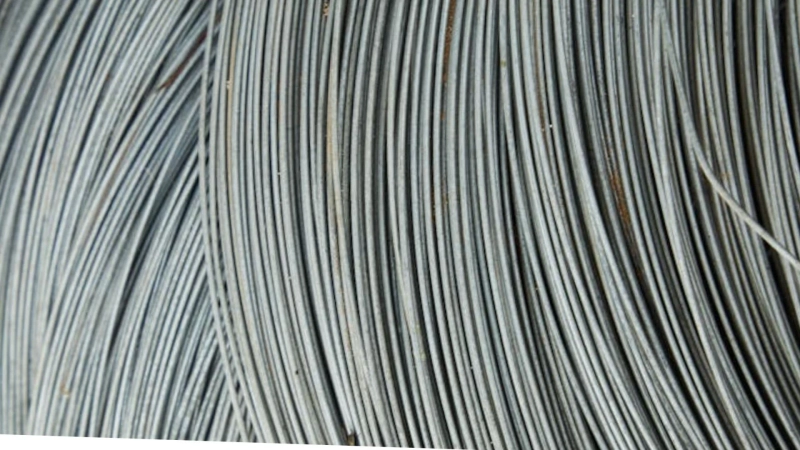

For industrial wire, the journey continues through hot rolling and cold drawing.

- Hot Rolling: The semi-finished steel billets are reheated and passed through rolling mills to reduce their thickness and form long rods.

- Cold Drawing: After cooling, the rods are further processed through dies to achieve the desired diameter and finish. This step enhances the wire’s strength, flexibility, and surface quality.

Different grades of wire are produced depending on their application—be it for construction reinforcement, electrical wiring, automotive components, or specialized industrial machinery.

This stage is where precision truly matters. Even the slightest variation in diameter or surface texture can affect performance, so manufacturers use advanced machinery and continuous monitoring systems to maintain exact tolerances.

5. Heat Treatment and Surface Finishing

To give steel wire its final characteristics, it undergoes various heat treatments such as annealing, quenching, and tempering. These processes help to improve ductility, tensile strength, and resistance to wear and fatigue.

After heat treatment, surface finishing techniques are applied. Wires might be coated with zinc (galvanizing) for corrosion protection, polished for aesthetic appeal, or treated chemically for specific industrial needs.

This is the stage where industrial steel and wire evolve from simple metal strands into reliable components capable of performing under extreme conditions.

6. Quality Assurance and Testing

Before reaching the market, every batch of steel and wire goes through rigorous quality checks. Tests are conducted for:

- Tensile strength – to ensure it can handle stress and load.

- Ductility – to confirm flexibility without breaking.

- Corrosion resistance – especially for outdoor or marine applications.

Modern steel and wire manufacturers rely heavily on automated inspection systems, ensuring uniformity and safety in every product.

7. The Final Stage: Applications Across Industries

The finished product now embarks on its next journey—into various industries that shape our daily lives. Industrial steel and wire are used in:

- Construction: Reinforcing bars, mesh, and cables for bridges and buildings.

- Automotive: Springs, fasteners, and tire cords.

- Electrical: Conductors, armoring, and grounding systems.

- Manufacturing: Tools, machinery, and equipment parts.

From the tallest skyscrapers to the smallest electronics, steel and wire are silently powering progress. Their durability, adaptability, and cost-efficiency make them essential to modern civilization.

8. Sustainability: Recycling for the Future

Today, the steel and wire industry is also leading the way in sustainability. Steel is 100% recyclable without losing its properties, which significantly reduces waste and conserves natural resources. Modern production methods aim to lower carbon emissions, use renewable energy, and promote circular manufacturing systems.

This commitment to sustainability ensures that the journey of steel continues responsibly—supporting industries while protecting the planet.

Conclusion

From raw iron ore to high-performance industrial wire, the transformation process reflects the perfect blend of science, technology, and craftsmanship. It’s a journey of strength, precision, and endless innovation that keeps industries moving forward.

At Krueger, we take pride in delivering excellence in every strand of steel and wire products we produce. Our commitment to quality, precision, and innovation has made us a trusted name in the industrial sector. Whether you need custom wire solutions or dependable steel products, Krueger ensures every product meets the highest standards of performance and durability—built to support your success.