finished stone

Finished Stone and Their Suitable Applications

Natural stones like granite, marble, limestone, quartzite, and sandstone are created by nature. These stones are mined from the earth and subjected to processing at the stone factories. These stone block are mined and cut into slabs and then sent for processing after which they come out as different finished stone. The process of stones finish makes them fit and suitable for different construction purposes like cladding stones and kitchen worktops.

Finishing of Stones-Significance

The finishing process involves a mechanical technique that gives the natural stones different types of finishes for both interior wall cladding and exterior design works. The functionality of the stone can be clearly redefined by the textural modification achieved in the finishing process. The surface finished stone are created to suit different requirements; those that are not slippery, light-reflecting surfaces, toning down the natural chrome, and sometimes softening or intensifying hues of cream and white, so that they can fit the right use, whether as cladding stones, kitchen worktops, backsplashes or bathroom surfaces, among many others. From times of old, natural stones have paved their way into homes, offices, and historical monuments for utilitarian and decorative purposes. The different texture of the natural stone enhances the longevity and aesthetics of the design.

AQUABELLA QUARTZITE

|

BELVEDERE GRANITE

|

BLUE ROMA QUARTZITE

|

Natural Stones Finish

The natural stone slab installed without any finishing processor in the absence of any treatment is called a rough finished stone. The stones are quarried from the mountains and sliced into slabs of desirable dimension. Then the finishing process begins for the stones which become suitable for stone wall cladding or cobblestones. The types of finishing available in natural finishing are Riven Finishing and Sawn finishing.

-

Riven Stones Finish

In Riven finished stone, the surface is designed for shining slate and quartzite tiles. The finish is derived from the point of division at which the blocks are dissected. The finish has other popular names like river cleft, natural cleft, or split face. This uneven surface is suitable for floor designs, the patterns on this design are not engineered but created naturally while mined. Certain granites and marbles are available with clefting which are limited for wall installations and pavements.

-

Sawn Stones Finish

Sawn finishing of stones is achieved by cutting the stone into tiles with a gang saw or block cutter. Granite and sandstone come in this finish and are used for decorating the garden, patio, and pavements. A split-face finished stone is created by splitting stone by hand or machine to achieve a natural-looking quarry texture. The back is flat with an uneven front. The look varies from one to another depending upon their usage and stone choice, whether it is internal wall cladding with marble wall panels or granite cladding stones, the result could be different.

JURA BLUE / GREY LIMESTONE

|

SEMI-RIJO LIMESTONE

|

SEMI -RIJO EXTRA LIMESTONE

|

Stone Block Can Also Be Given:

-

Satin Floor Finish

These finished stone are often described as silky or velvety and are very durable, so they can be used in areas with high foot traffic like entrances and playrooms. The light reflecting the capability of cladding stones that receive this finish is between that of matte and polished finishes.

-

Concrete Finished

Sandblasted finishing, one of the prominent finishes given to concrete, also known as abrasive blasting, gives a textured surface with a softened gloss. This uneven but tidy appearance is created using a high-pressure blast of sand to the natural stone. This sandblasted finish is suitable for high traffic areas when the treatment involves a high-pressure water jet with sand on the stone resulting in a finish that softens the chrome and characteristics of the stone.

-

Bush-Hammered Finishing of Stones

Bush-hammering uses a specialised hammer to create a highly textured finished stone, ideal for outdoor applications like walkways because of its anti-skip feel. This finish will fade the colour of the stone much more than honed. The cladding stone given this finish will also have a rougher, but more uniform surface than leathered finish. This type of finishing can be given to any stone.

-

Tumbled Stone Block

The most common stones that are tumbled are marble, granite, quartzite and travertine. Also recognized as Antique finish, tumbled finishing is given to cladding stones for an aged, rustic appearance.

-

Rigato Finishing

This is a type of machine finish that gives the stones a lined pattern. In between the lines, the texture feels rough.

-

Tooled Stone Block

Tooled finished stone is obtained by using a chisel which creates parallel lines that are either horizontal or vertical, on the surface of the stone.

-

Brushed Stones Finish

Brushed – A brushed finish can be used to create a textured look. The stone’s texture is soft to the touch, thanks to equipment like wire wheels and brushes, giving it a casual, worn appearance. In some cases, a brushed finish can be mixed with other finishes. Cladding stones with a brushed surface have a somewhat bumpy appearance. It usually has a finish of smooth and silky ridges and veins rather than being abrasive to the touch. A brushed finish, unlike polished or honed, usually lacks shine.

-

Flamed Finished

Flamed finished is a thermal finish given to natural stones that are rough and shiny. It is done to obtain rough-textured surfaces, commonly known for external use to reduce slippery surface concerns. This type of flamed granite finish is created by introducing increased temperature flame to the stone surface which results in a shock and causes internally embedded crystals to break or fracture creating a deeply textured surface. This is a useful technique to hide the flaws like imperfections and tonal variations on the natural stone. In stones with golden tallow hues like honey granite, the oxidation iron saturates the yellow to turn pale orange or pink creating a dramatic theme of colours. A flamed finished stone can be used for kitchen countertops as well as wall and floor tiles.

ANGOLA SILVER GRANITE

|

VOLAKAS MARBLE

|

CALIZA MARBELLA MARBLE

|

Check out our stone collection if you are looking to purchase stones for your home renovation or kitchen and bathroom worktops fabrication. Email info@work-tops.com for any assistance.

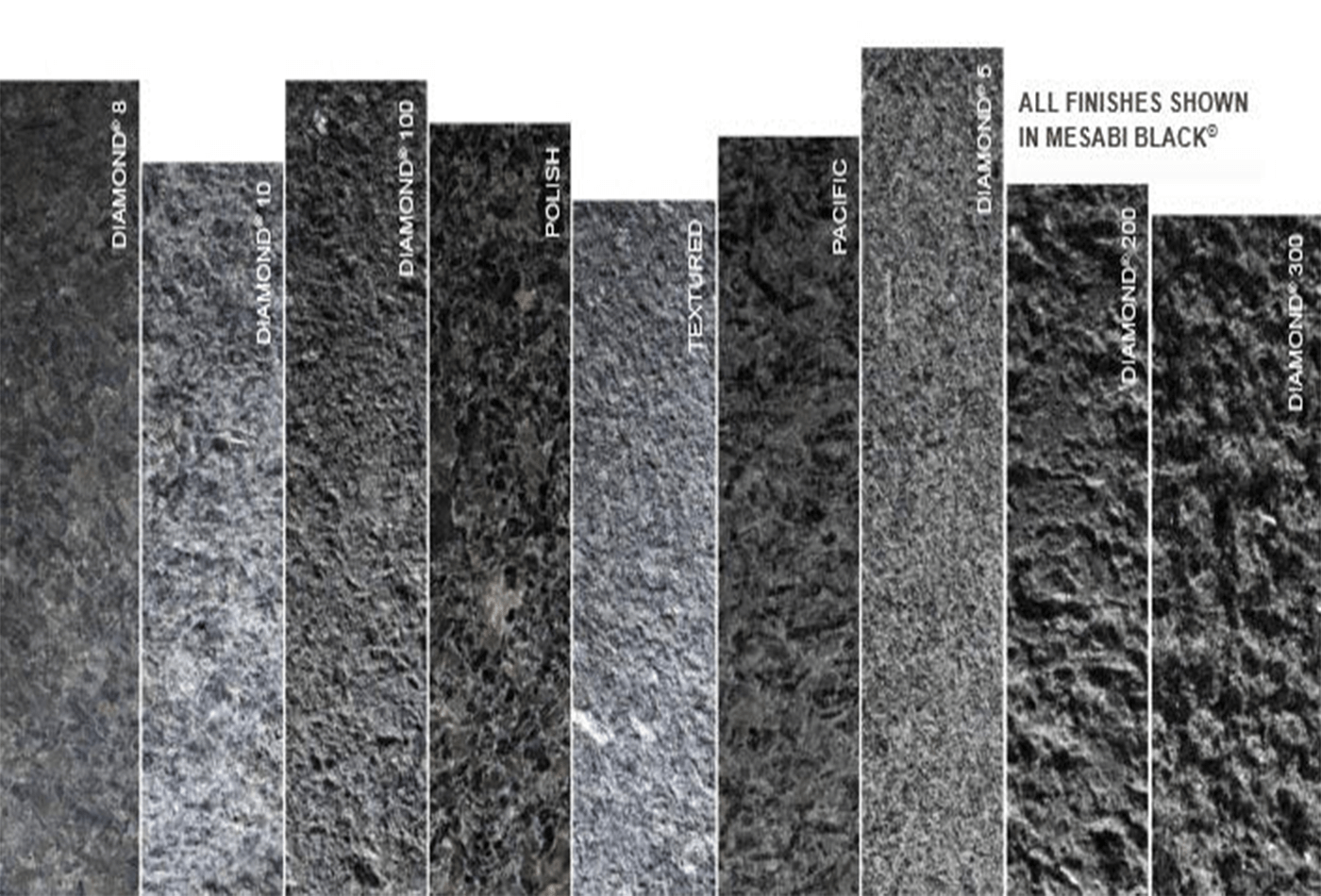

Mechanical Finishing of Stones

Mechanical finishing renders a smooth and glossy finish with different textures. This brings out the attributes of the stone to light. The popular finishing textures of natural stones available in mechanical finishing are Honed, Polished, and Leathered finished.

-

Honed Finished Stone

Honed finished stone is an ideal choice for a matted and smooth surface with lighter shades. The stones like granite, marble, limestone, slate, and travertine are used as cladding stones for busy floors and stairs. Sanding and grinding create a smooth finish but with less glossy or reflective results. This finish is a great pick for ease of maintenance, and busy traffic applications. It has a satin-smooth surface with a minimal reflection of light. Honed surfaces serve their purpose as the exterior in warm surroundings, tabletops, residential flooring, and interior wall cladding. Implementing different grades of abrasiveness under engineering conditions.

BALMORAL RED GRANITE

|

PARADISO CLASSIC GRANITE

|

INDIAN JET BLACK GRANITE

|

-

Leathered Finished

A leathered finished stone is created by brushing the slab with various brushes like diamond-tipped brushes that are used on top of honed granite to create the stone’s delicate, dimple-like pattern. The result of this process is an undulating, soft, seamless, and smooth-looking surface. This is a recent style that is getting greater favour in the design industry. It boasts a delicate gloss that is somewhat less than polished granite but also includes a rough appearance.

-

Polish Finish

Polish finish is concerned with a glossy surface that comes from the use of abrasive materials. It is suitable for polished marble, travertine, granite polishing, and limestone to emphasise their natural colours and grains. The sanding and buffing process leads to glossy sheen or mirror-like reflective surfaces. Polishing is subjective to crystallised stones. The porosity of the natural stone slab is affected by polishing treatment. It naturally induces the colour and veining pattern of the stone. A polish finish gives a smooth, seamless, and reflective appearance to the stone. Polished granite and polished marble is highly assigned for busy areas like an office Reception desk or Enquiry and Help desk, but the popular areas of application for a polished surface are exterior or interior wall cladding, interior or exterior paving fireplace surrounds, domestic and commercial worktops, tabletops, bench tops, and kitchen countertops. A polished reflective finishing of stones brings out its colours. The intensity of granite polishing and other stones is dependent upon the number of mineral deposits. These are highly recommended for wall covering but avoided as flooring due to the slippery nature of the finished stone.

0

0