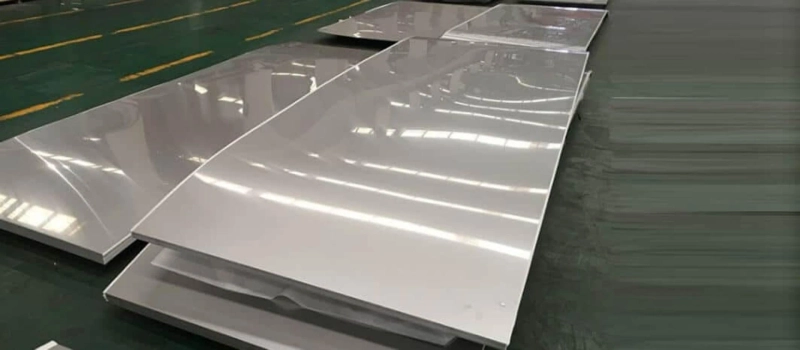

Stainless steel 420 sheets are corrosion-resistant, highly durable, and known for their hardness and machinability. They find applications in cutlery, medical instruments, tooling, industrial equipment, and architecture.

Properties of Stainless Steel 420 Sheets

- Corrosion Resistance: Stainless Steel 420 Sheets exhibit excellent corrosion resistance, making them suitable for applications in corrosive environments. They can withstand exposure to moisture, chemicals, and certain acids, making them ideal for chemical processing, marine, and food processing industries.

- High Hardness: Stainless steel 420 sheets are known for their high hardness level. They can be heat-treated to achieve optimal hardness, making them suitable for applications requiring wear resistance, abrasion, and impact. This property makes them popular in industries such as cutlery, surgical instruments, and molds.

- Strength and Durability: Stainless steel 420 sheets possess good tensile strength and mechanical properties. They offer a combination of strength and durability, making them suitable for applications that require structural integrity and long-lasting performance. Industries such as construction, automotive, and machinery benefit from these properties.

- Machinability: Stainless steel 420 sheets have good machinability, allowing for easy fabrication and forming processes. They can be readily cut, welded, and shaped into desired forms, making them versatile for various manufacturing applications. Industries such as fabrication, aerospace, and automotive utilize these sheets for parts and components.

- Heat Resistance: Stainless steel 420 sheets exhibit decent heat resistance, enabling them to withstand elevated temperatures without significant deformation or loss of strength. This property makes them suitable for high-temperature applications like heat exchangers, furnaces, and exhaust systems.

Applications of Stainless Steel 420 Sheets

- Cutlery and Kitchenware: Stainless steel 420 sheets are commonly used to produce cutlery, knives, and kitchen utensils. Their high hardness, corrosion resistance, and ease of maintenance make them ideal for food preparation and cooking equipment.

- Medical and Surgical Instruments: The exceptional hardness and corrosion resistance of stainless steel 420 sheets make them well-suited for medical and surgical instruments. These sheets are used to manufacture surgical blades, dental instruments, orthopedic implants, and other medical tools.

- Tooling and Molds: Stainless steel 420 sheets are widely used in the tooling industry to make molds, dies, and machine components. Their hardness, wear resistance, and dimensional stability make them suitable for producing plastic injection molds, stamping dies, and forming tools.

- Industrial Equipment and Machinery: Stainless steel 420 sheets find applications in various industrial equipment and machinery. They are used for fabricating parts and components in construction, automotive, oil and gas, and chemical processing.

- Architectural and Decorative Applications: Stainless steel 420 sheets are often employed in architectural and decorative applications due to their aesthetic appeal, corrosion resistance, and durability. They are used for cladding, interior design elements, signage, and exterior building features.

Stainless Steel 420 Sheets possess corrosion resistance, high hardness, strength, durability, machinability, and heat resistance. These sheets find applications in various industries, including cutlery, medical instruments, tooling, industrial equipment, and architectural projects.