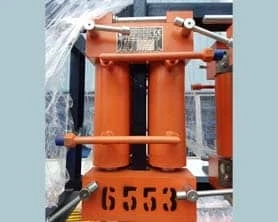

Exploring the Different Types of Hydraulic Jacks and Their Specific Uses

Hydraulic jacks are powerful tools used for lifting heavy objects with ease and precision. They are widely used in various industries, construction sites, and automotive ...

Hydraulic jacks are powerful tools used for lifting heavy objects with ease and precision. They are widely used in various industries, construction sites, and automotive ...