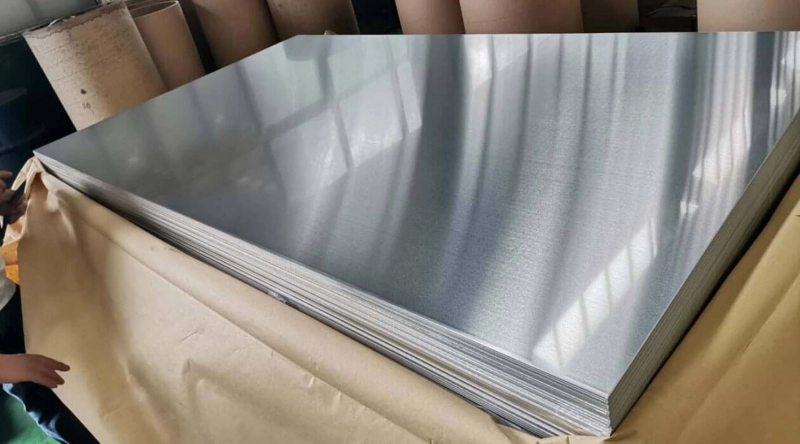

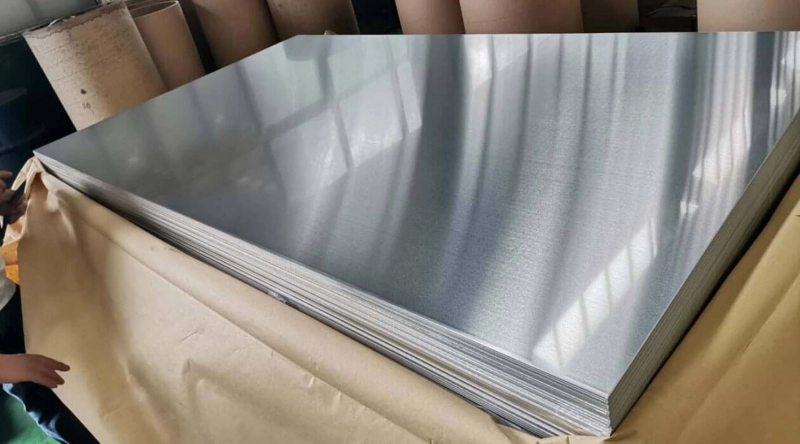

Everything About Aluminum Alloy Sheets

Aluminum alloy sheets are thin pieces of metal made from a combination of aluminum and elements such as copper, magnesium, silicon, or zinc. These alloys ...

Aluminum alloy sheets are thin pieces of metal made from a combination of aluminum and elements such as copper, magnesium, silicon, or zinc. These alloys ...