Precision in construction is essential to ensure the safety, durability, and efficiency of concrete structures. One of the most critical aspects of achieving this precision lies in the accurate detailing of reinforcement bars, commonly known as rebar. Rebar detailing involves creating comprehensive drawings and schedules that specify the size, shape, quantity, and placement of reinforcement bars within concrete elements. The adoption of Rebar Detailing CAD Services has transformed this process, enabling engineers, fabricators, and contractors to enhance construction accuracy and streamline project workflows.

The Role of Rebar Detailing Services in Construction

Rebar Detailing Services provides the detailed instructions necessary for fabricating and installing reinforcement bars correctly. These services translate structural designs into actionable plans, reducing the risk of errors that can compromise structural integrity or cause costly delays. Rebar Shop Drawings Services are a fundamental component, offering detailed views of each reinforcement bar, including bends, lengths, and positioning within the concrete framework. This clarity ensures that construction teams can follow the design precisely, minimizing misplacement and rework.

The detailing process also involves creating Rebar Detailing drawing services that include all necessary annotations, dimensions, and specifications. These drawings serve as a communication tool between structural engineers, fabricators, and site teams, ensuring everyone understands the reinforcement requirements. Without such detailed documentation, the risk of misinterpretation increases, which can lead to structural failures or costly rework.

Advantages of 3D Rebar Modeling Services

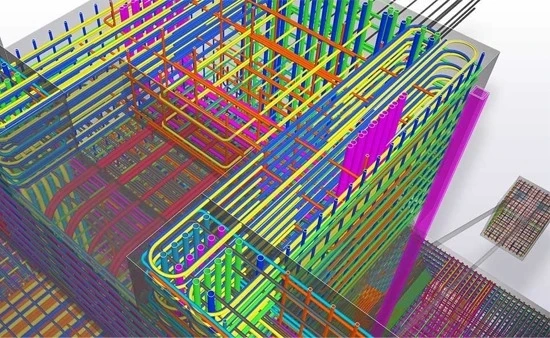

The introduction of 3D Rebar Modeling Services has significantly improved the visualization and accuracy of reinforcement layouts. Unlike traditional 2D drawings, 3D models provide a realistic representation of how rebar fits within the structure, allowing engineers to detect potential clashes with other building elements early in the design phase. This proactive approach prevents costly modifications during construction.

3D Rebar Modeling Services also enhance collaboration among architects, structural engineers, fabricators, and site supervisors by providing a shared, interactive model. This shared understanding helps maintain project timelines and reduces misunderstandings. Additionally, Rebar 2D and 3D Modeling Services offer flexibility, allowing teams to choose the most suitable format based on project complexity and requirements.

The use of 3D models also facilitates integration with Building Information Modeling (BIM) systems, which are increasingly becoming standard in large-scale construction projects. This integration allows for better coordination between different disciplines, such as electrical, plumbing, and HVAC, reducing clashes and improving overall project efficiency.

Comprehensive Reinforcement Detailing Services

Reinforcement Detailing Services extend beyond drawings to include Bar Bending Schedule Services, which are vital for the fabrication process. A bar bending schedule lists all reinforcement bars required, detailing their shapes, lengths, and bending angles. This schedule guides fabricators in cutting and bending bars accurately, reducing material waste and ensuring timely delivery to the construction site.

When combined with detailed Rebar Detailing drawing services, bar bending schedules contribute to a smoother construction process by minimizing errors and delays. Accurate schedules also help control costs by optimizing material usage and reducing wastage.

Moreover, Reinforcement Detailing Services often include quality checks and compliance verification to ensure that the detailing adheres to relevant codes and standards. This is crucial for maintaining structural safety and meeting regulatory requirements.

Benefits of Rebar Detailing Outsourcing Services

Many construction firms leverage Rebar Detailing Outsourcing Services to access specialized expertise and reduce operational costs. Outsourcing allows companies to focus on core activities while entrusting rebar detailing to professionals equipped with the latest CAD technology and industry knowledge.

Outsourcing offers scalability, enabling firms to handle projects of varying sizes without overburdening in-house teams. Specialized Rebar Detailing CAD Services providers ensure high-quality deliverables that comply with project specifications and standards, enhancing overall project quality.

Additionally, outsourcing can accelerate project timelines by providing round-the-clock work cycles, especially when partnering with firms in different time zones. This continuous workflow can be a significant advantage in meeting tight deadlines.

Precision Through Rebar CAD Shop Drawing Services

Rebar CAD Shop Drawing Services produce fabrication-ready drawings with exact specifications for cutting, bending, and placing reinforcement bars. CAD technology ensures these drawings are accurate, consistent, and easy to update if design changes occur.

Integration of CAD shop drawings with Building Information Modeling (BIM) further improves coordination among different disciplines, reducing clashes and enhancing project efficiency. This precision helps avoid common issues such as misinterpretation of drawings and incorrect bar placement, leading to safer and more durable structures.

These shop drawings also facilitate automated quantity take-offs, which help in accurate material estimation and procurement, reducing the risk of shortages or excess inventory on-site.

How Rebar Detailing Drawing Services Improve Project Outcomes

Rebar detailing drawing services provide clarity and precision that directly impact project success. Detailed drawings reduce guesswork on-site, minimizing errors during reinforcement installation. They also serve as a reference for quality control inspections, ensuring compliance with design and safety standards.

Moreover, these drawings facilitate better material management by specifying exact quantities and specifications, which helps in procurement and inventory control. This reduces waste and optimizes project costs.

By providing detailed and accurate documentation, Rebar Detailing drawing services also support dispute resolution and claims management by offering clear evidence of design intent and execution requirements.

Advantages of Rebar Detailing CAD Services

- Enhanced Accuracy: CAD tools reduce human errors and improve detailing precision.

- Time Savings: Automated processes accelerate drawing creation and revisions.

- Improved Visualization: 3D modeling helps identify design conflicts early.

- Cost Efficiency: Accurate detailing minimizes material wastage and rework.

- Better Collaboration: Digital drawings improve communication among stakeholders.

- Scalability: Outsourcing allows flexible resource management for projects of all sizes.

- Regulatory Compliance: Ensures adherence to local and international building codes.

- Improved Quality Control: Detailed drawings facilitate inspections and verifications.

Disadvantages of Rebar Detailing CAD Services

- Initial Costs: Investment in CAD software and skilled personnel can be high.

- Training Requirements: Teams may need time to master advanced CAD tools.

- Technology Dependence: Software issues can cause project delays.

- Outsourcing Challenges: Communication gaps and time zone differences may affect timelines if not managed well.

- Data Security Risks: Sharing sensitive project data with third parties requires robust security measures.

Case Study: Streamlining Rebar Detailing Through Outsourcing

A construction company working on a large commercial project faced delays due to limited in-house detailing capacity. They outsourced their Rebar Detailing CAD Services to a specialized firm offering Rebar Shop Drawings Services and 3D Rebar Modeling Services.

The outsourcing partner delivered detailed, fabrication-ready drawings and accurate Bar bar-bending schedule Services within tight deadlines. Early clash detection through 3D modeling improved coordination with other trades, reducing on-site conflicts. The precise bar-bending schedules minimized material wastage by 15%, and the project was completed 10% ahead of schedule.

This case highlights how Rebar Detailing Outsourcing Services can enhance accuracy, reduce costs, and improve project delivery.

Frequently Asked Questions (FAQs)

Q1: What are Rebar Detailing Services?

A1: They involve creating detailed drawings and schedules that specify the size, shape, quantity, and placement of reinforcement bars in concrete structures.

Q2: How do 3D Rebar Modeling Services improve construction?

A2: They provide realistic visualization, help detect clashes early, and enhance communication among project teams.

Q3: Why outsource Rebar Detailing CAD Services?

A3: Outsourcing offers access to expert teams, advanced technology, cost savings, and scalability.

Q4: What is included in Bar Bending Schedule Services?

A4: Detailed lists of reinforcement bars with shapes, lengths, and bending angles for accurate fabrication.

Q5: Can Rebar CAD Shop Drawing Services integrate with BIM?

A5: Yes, integration improves coordination and reduces clashes during construction.

Q6: How do Rebar Detailing drawing services help with quality control?

A6: They provide clear documentation for inspections, ensuring reinforcement is installed as per design specifications.

Conclusion

Accurate rebar detailing is fundamental to constructing safe and durable concrete structures. Rebar Detailing CAD Services, including Rebar Shop Drawings Services, 3D Rebar Modeling Services, and Bar Bending Schedule Services, provide the precision and clarity needed to execute reinforcement designs flawlessly. Whether handled in-house or through Rebar Detailing Outsourcing Services, these solutions enhance construction accuracy, reduce costs, and improve project timelines. Embracing these advanced detailing services is essential for modern construction projects aiming for excellence and efficiency.