In the modern global economy, supply chains are the lifelines of industries. From raw material procurement to final delivery, every step of the process must run smoothly to ensure efficiency, cost-effectiveness, and reliability. To achieve this, businesses are increasingly relying on advanced equipment and technology. Among the critical tools that contribute significantly to the smooth functioning of supply chains are the weighbridge and the ice maker. While they serve very different purposes, both play essential roles in improving supply chain performance, particularly in industries where accuracy and quality are paramount.

The Critical Role of Weighbridges in Supply Chains

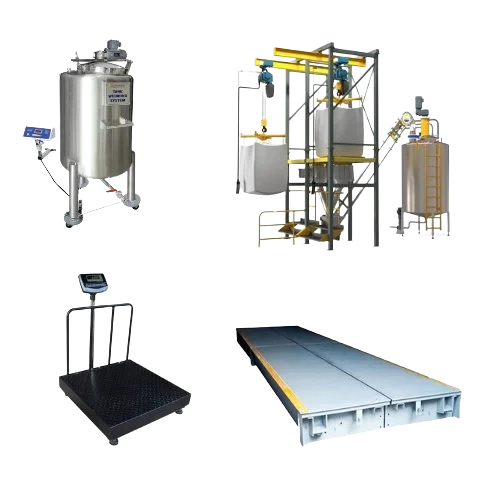

A weighbridge is far more than just a large weighing machine. It is a central part of logistics and transportation management. For industries that deal with bulk cargo—such as mining, agriculture, construction, and manufacturing—accurate weight measurement is essential for efficiency, compliance, and safety.

- Accurate Load Management: A weighbridge ensures that trucks carry the right load. Overloaded vehicles not only risk fines but also increase fuel consumption and wear and tear on infrastructure. Underloading, meanwhile, results in inefficient transportation and higher per-unit costs.

- Compliance with Regulations: Transport authorities around the world enforce strict weight limits for vehicles. Using a weighbridge ensures that companies comply with these rules, avoiding penalties and contributing to road safety.

- Fairness in Trade: Many industries rely on weight as the basis for transactions. Whether it is grains, minerals, or raw materials, the weighbridge provides reliable data that prevents disputes and ensures fairness.

- Digital Integration: Advanced weighbridge systems today are fully integrated with software solutions, RFID tracking, and real-time data analysis. This allows companies to monitor and optimize supply chain operations, leading to improved decision-making.

By providing accuracy, transparency, and compliance, a weighbridge strengthens the backbone of supply chain operations.

Ice Makers and Their Role in Supply Chain Efficiency

While a weighbridge manages logistics accuracy, the ice maker supports supply chain quality by ensuring proper preservation. In industries like food processing, fisheries, pharmaceuticals, and healthcare, maintaining the right temperature is non-negotiable. A reliable ice maker is the solution to keeping products safe and fresh throughout the supply chain.

- Food Industry Applications: From seafood to poultry and dairy, ice plays a vital role in maintaining product freshness. An ice maker ensures a steady supply of hygienic ice, helping businesses reduce spoilage and waste.

- Healthcare and Pharmaceuticals: Vaccines, medicines, and biological samples often require cold storage during transport. High-performance ice makers provide the cooling needed to maintain product integrity across the supply chain.

- Hospitality and Retail: Restaurants, supermarkets, and hotels also rely heavily on ice makers to serve customers and preserve food. By ensuring continuous ice production, these machines support last-mile efficiency.

- Industrial Uses: Beyond food and healthcare, ice makers are used in certain industries for process cooling. For instance, in construction, ice is added to concrete to control temperature during curing.

By safeguarding freshness and maintaining quality standards, an ice maker plays a crucial role in protecting goods as they move through the supply chain.

The Synergy of Weighbridges and Ice Makers in Supply

Chains

Although the functions of weighbridges and ice makers are different, their combined impact on supply chain efficiency is undeniable. Consider the seafood industry as an example. Trucks transporting fish are weighed at a weighbridge to ensure compliance with legal load limits and to provide accurate trade records. At the same time, the fish is preserved with ice produced by an industrial ice maker, ensuring the product arrives fresh at its destination.

This combination allows businesses to avoid penalties, reduce costs, and guarantee product quality—all of which are essential in maintaining an efficient and trustworthy supply chain.

Technological Advancements Driving Efficiency

Modern versions of these machines have been designed to further support supply chain optimization.

- Smart Weighbridges: Automated ticketing systems, vehicle recognition via RFID, and integration with enterprise resource planning (ERP) software make weighing faster, more accurate, and less prone to human error.

- Energy-Efficient Ice Makers: Today’s ice makers are designed to consume less energy and water while delivering higher output. They also offer better hygiene with advanced filtration systems and the ability to produce different ice types tailored to industry needs.

With these advancements, both weighbridges and ice makers contribute not only to efficiency but also to sustainability, which is increasingly important in modern supply chains.

Long-Term Business Benefits

Investing in advanced weighbridges and ice makers provides businesses with several long-term advantages:

Cost Savings – Reduced fines, fuel savings, and minimized spoilage directly translate into lower operational costs.

Customer Trust – Delivering accurate weights and fresh, well-preserved products builds credibility and long-term relationships with clients.

Data-Driven Efficiency – Modern weighbridge and ice maker systems provide actionable data that can be used to forecast demand, optimize loads, and reduce waste.

Sustainability – Energy-efficient machines help businesses meet environmental standards while lowering utility bills.

Supply chain efficiency is no longer just about moving goods from one point to another—it is about doing so with precision, safety, and reliability. The weighbridge ensures that goods are transported within safe and legal limits, while the ice maker guarantees that products maintain their quality throughout storage and transit. Together, these machines play a vital role in reducing waste, cutting costs, and enhancing customer trust.

For industries aiming to remain competitive in a demanding marketplace, investing in advanced weighbridges and high-performance ice makers is not just an operational decision—it is a strategic move toward supply chain excellence.