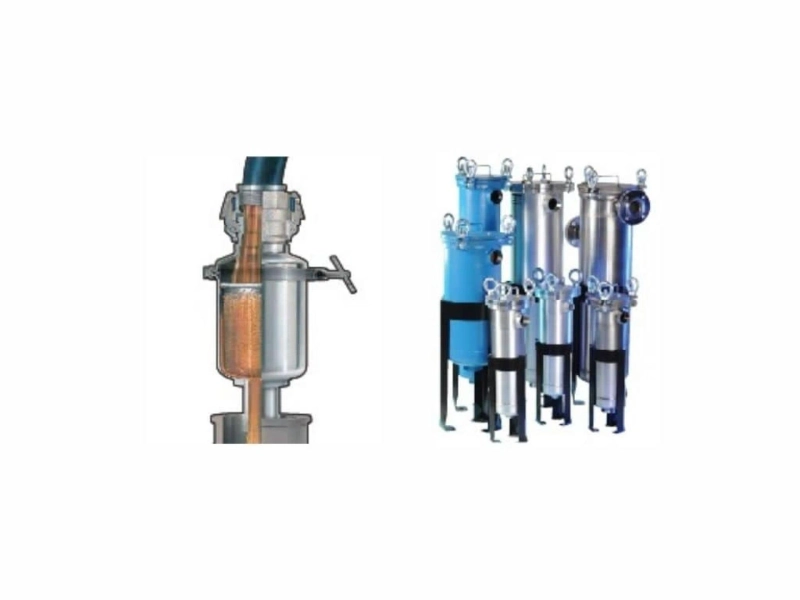

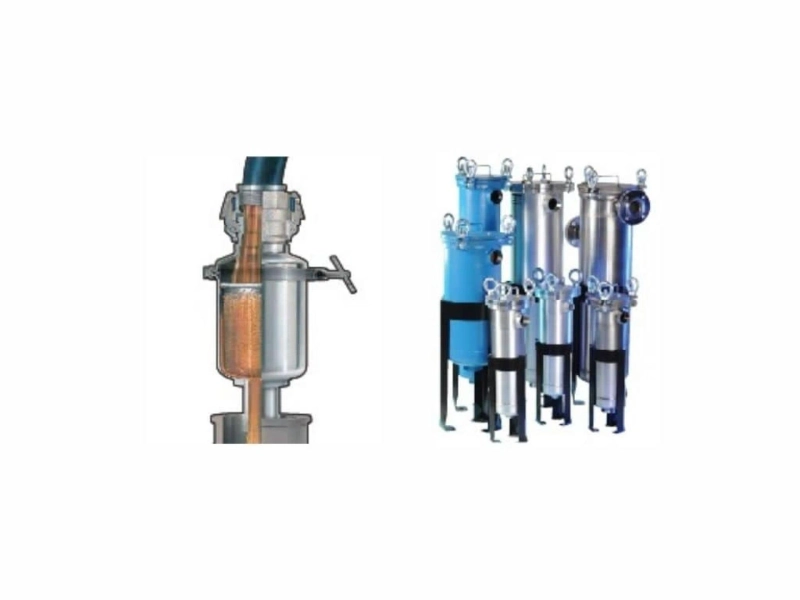

Bag Filter Housing

Bag Filter housings are as yet perhaps the most savvy way of sifting residue and particulate matter from gas streams ...

Bag Filter housings are as yet perhaps the most savvy way of sifting residue and particulate matter from gas streams ...