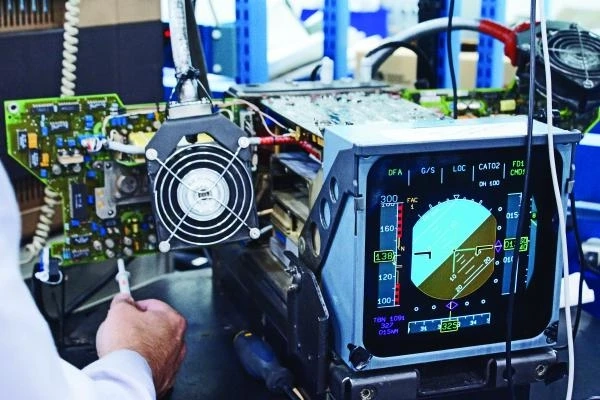

Avionics are electronic systems used on aircraft, spacecraft, and satellites. These systems include navigation, communication, flight control, and monitoring systems. Electronic components are the individual parts or devices that make up electronic systems. Examples of electronic components include transistors, capacitors, and resistors. These components are used in avionics systems to control and monitor various aspects of the aircraft\'s operation.

Avionics And Electronic Components are crucial for the safe and efficient operation of aircraft. They provide pilots with the information they need to navigate, communicate, and control the aircraft. Some examples of avionics systems include:

Navigation Systems

These systems use a combination of GPS, radar, and other sensors to determine the aircraft\'s position and provide information to the pilot about the aircraft\'s location, speed, and altitude.

Communication systems

These systems allow pilots to communicate with air traffic control, other aircraft, and ground-based personnel. They include radios, transponders, and other devices.

Flight control Systems

These systems help pilots control the aircraft\'s flight path and altitude. They include autopilots, flight management systems, and other computer-controlled devices.

Monitoring Systems

These systems provide pilots with information about the aircraft\'s performance and status. They include engine monitoring systems, weather radar, and other sensors.

Electronic Components

Electronic components are the building blocks of avionics systems. They include things like semiconductors, resistors, capacitors, and other devices that are used to control and process electronic signals. These components are used in a wide range of avionics systems, from navigation systems to flight control systems. They are also used in other electronic systems, such as those found in automobiles and consumer electronics.

In recent years, avionics and electronic component technology has been advancing rapidly. For example, advanced sensors, new types of transistors, and other new technologies have led to the development of more capable, efficient, and reliable avionics systems. Additionally, the use of software-defined radios and other software-based technologies has made avionics systems more adaptable and customizable.

Avionics Industry

The avionics industry is constantly evolving with new technologies and advancements that enable new capabilities and improve the performance of existing systems. Some of the recent trends and developments in the avionics industry include:

Increased use of Digital Technology

Many avionics systems are moving away from analog technology and towards digital technology. This allows for more accurate and reliable data processing, as well as the ability to integrate multiple systems and functions into a single digital platform.

Greater Use of Embedded Systems

Embedded systems are small, specialized computers that are integrated into other devices. They are increasingly being used in avionics systems, allowing for more efficient and compact designs.

Advancements in Sensors

Avionics systems rely heavily on sensors to gather information about the aircraft\'s environment and performance. Advances in sensor technology are allowing for the development of more accurate, reliable, and compact sensors.

Greater Use of Data Networks

Avionics systems are increasingly using data networks to share information and communicate with other systems. This allows for more efficient and effective communication between different systems and components.

More Advanced Software

The use of advanced software is becoming increasingly important in avionics systems. Software-based technologies, such as software-defined radios, are making avionics systems more adaptable and customizable.

Cybersecurity

The increasing use of digital technology in avionics systems has led to concerns about cybersecurity. Ensuring the security of avionics systems from cyber-attacks is becoming increasingly important.

In addition to these trends, the avionics industry is also facing various challenges such as the high cost of development and certification and the need for increased safety and reliability. However, the industry continues to evolve and advancements in technology will continue to drive the industry forward, leading to the development of more advanced and capable avionics systems.

Fixed-Wing Aircraft Parts

In addition to the basic components mentioned above, fixed-wing aircraft parts also have several other important parts that are essential for safe and efficient operation. Some of these include:

Propeller or jet turbine: propels the aircraft forward and provides thrust for flight.

Fuel system: stores and delivers fuel to the engine(s)

The electrical system provides power for various systems and equipment on the aircraft, such as navigation and communication systems, lights, and instruments.

Flight control system: allows the pilot to control the aircraft\'s movements and includes the ailerons, elevators, and rudder.

Navigation and communication systems: allow the pilot to navigate and communicate with air traffic control and other aircraft.

Avionics: various electronic systems that are used for navigation, communication, and aircraft control.

Environmental control system: regulates the temperature, humidity and pressure inside the cabin.

Emergency systems: includes emergency exits, lighting, and equipment such as life rafts, life vests, and oxygen masks.

Safety equipment: includes fire extinguishers, smoke detectors, and emergency locator transmitters.

Some of the parts that are specific to certain types of fixed-wing aircraft are:

Turboprop Aircraft: turboprop engines, are a combination of a gas turbine and a propeller.

Jet Aircraft: bypass engines, which are more efficient than traditional turbine engines and allow the aircraft to fly at higher speeds and altitudes.

Gliders: no engines, they are towed to altitude by a powered aircraft or launched using a winch or aero-tow.

Unmanned Aerial Vehicles (UAVs): payloads such as cameras or sensors, and navigation equipment for remote control or autonomous operation.

It\'s important to note that all these parts need to be regularly maintained, serviced, and inspected to ensure the safe and reliable operation of the aircraft. Propellers and jet turbines are both types of propulsion systems used in fixed-wing aircraft.

Propellers are mechanical devices that convert rotary motion into thrust. They consist of two or more blades that rotate around a central hub. The blades are designed to slice through the air, creating a difference in air pressure that propels the aircraft forward.

Propellers are powered by an engine, typically a reciprocating engine, which turns the propeller shaft. Propellers are commonly used in smaller, slower aircraft, such as single-engine and small twin-engine planes, as well as turboprop aircraft.

Jet turbines, also known as jet engines, work on the principle of action and reaction, also known as Newton\'s Third Law of Motion. In a jet turbine, the air is drawn into the front of the engine, compressed, mixed with fuel, and ignited. The combustion process creates hot gases that are expelled out of the back of the engine, creating thrust that propels the aircraft forward. Jet turbines are powered by either a gas turbine or a turbofan engine. They are commonly used in larger, faster aircraft, such as commercial airliners and military jets.

Each type of propulsion system has its own advantages and disadvantages. Propellers are generally more fuel-efficient and quieter than jet turbines, but they are not as fast or powerful. Jet turbines are able to achieve much higher speeds and altitudes, but they are also much more complex and require more maintenance.

A fuel system is a critical component of a fixed-wing aircraft. Its main function is to store and deliver fuel to the engine(s) in a controlled manner, allowing the aircraft to fly.

The fuel system typically consists of several key components:

Fuel tanks: store the fuel and are located in various parts of the aircraft, such as the wings, fuselage, and tail.

- Fuel pumps: transfer the fuel from the tanks to the engine(s)

- Fuel lines: transport the fuel from the tanks to the engine(s) and fuel pumps

- Fuel filters: remove impurities from the fuel before it reaches the engine(s)

- Fuel selector valves: allow the pilot to select which tank the fuel is drawn from

- Fuel quantity indicator: shows the amount of fuel remaining in the tanks

- Fuel shutoff valves: allow the pilot to turn off the fuel flow in case of an emergency.

There are two types of fuel systems: wet wing and dry wing. In wet wing systems, the fuel tanks are integrated into the structure of the wings, while in dry wing systems, the fuel tanks are separate from the wing structure and are located in other parts of the aircraft, such as the fuselage.

The fuel system is subject to strict regulations, which dictate the materials that can be used, the design of the system, and the maintenance procedures required to ensure safe and reliable operation.

It\'s important to note that the fuel system also needs to be designed and certified to withstand potential hazards such as fuel leaks, fire, and impact. Additionally, the fuel system needs to be regularly inspected and maintained to ensure it\'s in good working condition.