Why is laser cutting of metal the best use of a powerful laser technique?

Rache Corp assists relationships in the USA with making ideal laser cut or engraved designs and is delighted to offer laser cutting and scratching affiliations. The best laser cutting affiliations are exceptionally figured out for huge parts for laser cutting, laser drawing, attentive CNC machining, and okay beating. In like manner, we offer our clients limitless customization and personalization decisions. Similarly, we use current laser improvement structures that outfit our clients with several advantages.

laser welding services are enormous, whether to fix a chance to weld clinical contraptions or tackle different tangled conditions was scaled down welding or conventional welding can’t do what should be finished. However, the power from a laser is sufficient to convey, as per an overall perspective, cautious welding, with no pain point locales all over the head. In this way, laser welding is an ideal technique for welding parts made using metals or thermoplastics.

Taking everything into account, taking into account that laser welding utilizes laser support concentration to join the locale at the recognized edges of a part to influence changes and break something like two individual pieces of metal. Plus, laser shaft welding uses a focused light flood to relax metal together. Laser welding is a positive, flexible joining process in which metals are connected with laser sponsorship to make a welding joint. Since laser welding uses a laser shaft, no filtration materials are added with laser welding.

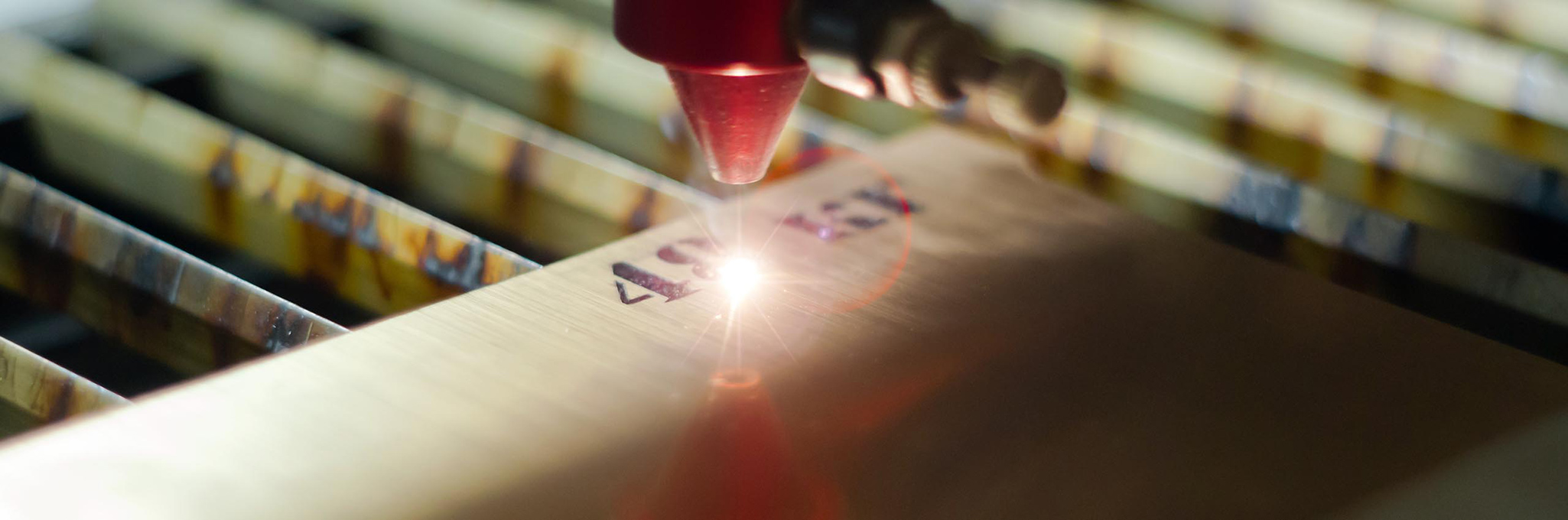

The laser cutting of metal with a high peak power of the pulse wave

The laser cutting of metal machine uses the laser bar exuded by the laser generator to zero in on the overwhelming thickness of the laser shaft light circumstances through the outer circuit structure. Press slows down, and wandering metal machines can utilize packaging and cutting high-temperature metal mixes more than laser cutters. Regardless of these metals, lasers can be used to cut different non-metal materials, from wood to plastic, and for stoneware creation.

Lasers can cut various materials and are routinely utilized on a few select metals: carbon steel, mild steel, treated steel, aluminum composites, carbon steel, and solidified steel. While cutting treated steel or aluminum, the laser shaft relaxes the material, and high-pressure nitrogen is used to blow the liquid metal out of the cut locale.

Precision laser welding is entirely used in the business since it can convey quality results rapidly. While working with high-exactness laser welding structures, you can perform endeavors like joining minor metals, ensuring trustworthy action since the mentioning believed is irrelevant to indent welding results.

The Precision laser welding is thoroughly utilized in the business since it can convey quality outcomes quickly.

High-accuracy laser welding structures are regularly utilized in applications requiring sheet metal creation and in auto and flying endeavors. Laser welding of the right parts can be applied to various metals, especially for welding some endeavoring to weld exciting metals. Laser welding for exactness welding of parts uses a related laser shaft from a flood of painful areas of strength for monochromatic photons as a vital place of union for welding.

Most helium spill testing applications use a mass spectrometer (spill locater) to see helium. The helium spill test is performed utilizing a mass spectrometer familiar with the presence of helium particles. The helium leak testing services are portrayed as seeing spills in various shut or fixed structures, including helium as a “tracer” gas. Its obsession is framed as it spills due to a break.

You can attempt a severe break test to ensure no great space, followed by a high vacuum helium spill test in a shut chamber using a helium mass spectrometer. We perform vacuum spill testing on several of our vast parts utilizing helium mass spectrometers. While various structures see spills, helium vacuum tests give sharp contemplations and Accuracy over the norm, irregular openings, and little breaks.

0