Advancements in PEI Injection Molding Surface Finish Matters!

Plastic injection molding is a versatile manufacturing process that has become indispensable in various industries, from automotive to medical devices. Recently, there has been a growing demand for precision and durability in injection-molded components, especially in applications with high temperatures. This demand has led to significant advancements in materials and processes, including using Polyetherimide (PEI) and high-temperature injection molding techniques, particularly by Chinese mold makers. Additionally, the quality of the injection mold surface finish plays a pivotal role in the overall performance and aesthetics of the final product. In this article, we will explore the critical aspects of PEI injection molding, high-temperature injection molding, the role of China mold makers in these developments, and the importance of injection mold surface finish.

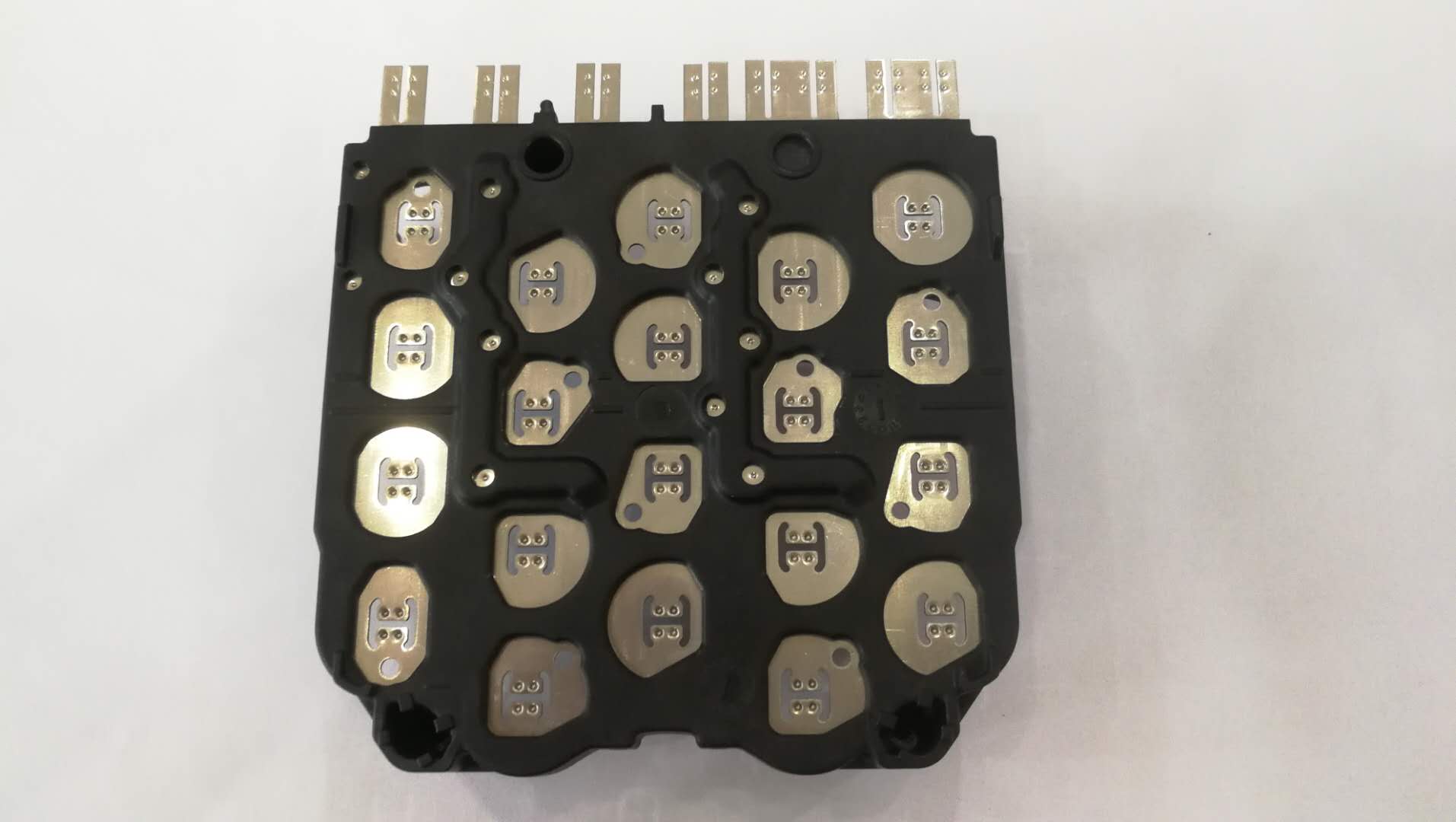

PEI Injection Molding

Polyetherimide (PEI), a high-performance engineering thermoplastic, has gained popularity in injection molding due to its exceptional properties. PEI injection molding offers a unique combination of high-temperature resistance, mechanical strength, chemical resistance, and electrical insulation, making it suitable for various demanding applications.

One of the main challenges in PEI injection molding is the material’s high melting point, typically around 217°C (423°F). Achieving proper melt flow and preventing premature material degradation is crucial. China mold makers have been at the forefront of developing molds and processes that can handle PEI effectively. This involves precise temperature control, specialized injection molding machines, and mold designs tailored to the material’s characteristics.

High-Temperature Injection Molding

High temperature injection molding goes hand in hand with materials like PEI and other thermoplastics such as PEEK (Polyetheretherketone) and PPS (Polyphenylene Sulfide). These materials are increasingly used in aerospace, electronics, and medical devices, where exposure to elevated temperatures is expected.

China mold makers have embraced high-temperature injection molding techniques to meet the growing demand for components that can withstand extreme environments. Critical factors in high-temperature molding include selecting the suitable material, optimizing melt flow, and ensuring the mold can handle high temperatures without deformation or deterioration.

The Role of China Mold Makers

China has emerged as a global leader in injection mold manufacturing, with many mold makers specializing in producing high-quality molds for various industries. China mold maker has been pivotal in advancing PEI and high-temperature injection molding techniques. Here are some reasons behind their prominence:

China mold maker has been pivotal in advancing PEI and high-temperature injection molding techniques.

Expertise and Experience: Many Chinese mold makers have decades of experience in mold design and manufacturing. They have honed their skills and acquired in-depth knowledge of materials and processes.

Cost-Effective Solutions: China is known for providing cost-effective solutions without compromising quality. This has made it an attractive destination for businesses looking to manufacture injection molds.

Injection Mold Surface Finish

While materials and processes are crucial in injection molding, the surface finish of the final product should not be overlooked. The injection mold surface finish affects not only the aesthetics but also the functionality and performance of the component. Here are some key points to consider:

Aesthetics: The surface finish of an injection-molded part contributes significantly to its visual appeal. Smooth, glossy finishes are often preferred for consumer products, while textured or matte finishes may be suitable for industrial or functional parts.

Functionality: Surface finish can impact the functionality of a part. For example, a polished surface may reduce friction and wear in moving components, while a textured surface might improve grip or adhesion.

Mold Release: Proper surface finish is essential for quickly releasing the molded part from the cavity. Inadequate surface finish can lead to issues such as part sticking or damage during demolding.

Material Selection: The choice of material, in combination with the desired surface finish, can influence the ease of achieving the desired result. Some materials are more amenable to specific surface treatments than others.

Post-Molding Processes: In some cases, additional post-molding processes like polishing, plating, or painting may be required to achieve the desired surface finish.

Conclusion

PEI and high-temperature injection molding have become essential manufacturing processes in industries that demand robust, high-performance components. China mold makers have played a significant role in advancing these techniques, leveraging their expertise, cost-effective solutions, and commitment to research and development. Furthermore, the injection mold surface finish should not be underestimated, as it directly impacts aesthetics and functionality. As technology continues to evolve, we can expect further innovations in materials, processes, and surface finish techniques, driving the plastic injection molding industry toward new heights of precision and performance.