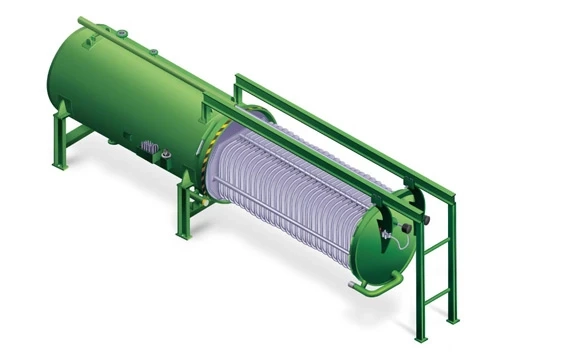

The high pressure filtration system is an important part of all oil milling units that deal in biodiesel, vegetable oil, and any other chemical or liquids. Since all the oil-bearing seeds are pressed for the separation of oil from the meal, a huge amount of particles resulting from the pressing process are also carried into the oil.

However, certain modifications can be made in the pressing operations structure to reduce the number of particles but some advanced cleaning or filtration is always required to remove all the undesired particles.

The problems that unwanted particles create in the oils

In case any particular oil is used as a fuel, these particles present in the oil will create a lot of nuisances by clogging the fuel filters while completely stopping the required flow of fuel to the engine. It will be a great distraction for the travelers on the way. On the other hand, if such is the case with any particular edible oil, it will affect the taste, overall quality, and look and feel of the food item prepared or fried using that oil. Therefore, all the oils must undergo an advanced filtration process carried out in a sophisticated PLC automatic filtration system.

3 major filtration methodologies

In oil language, the “foots” are the materials or particles that need to be minutely filtered or clean during the oil processing through a high-pressure filtration system. When the oil-bearing seeds are pressed, the oil and oilseeds are separated followed by the oil and foots\' separation process during the filtration. Depending on the degree of refinement and the overall cleaning required, the filtration of all vegetable oils and even biodiesel can be carried out in different ways. Out of these, 3 major filtration methodologies include the following:

- Settling

- Bag filters

- Cartridge filters

Settling

This is one of the most cost-effective and simplest oil filtration processes carried out to settle all the unwanted particles out of the oil. Settling might be carried out as a separate step when the oil is pressed. Carried out on a high pressure filtration system, it is an ongoing process performed when the oil is collected from the press.

Bag filter

A bag filter is a bag of certain porosity particles which makes the oil pass through the bag and grabs all the unwanted particles in the bag itself. One of the most preferred as well as recommended forms of the bag filter can be defined as old blue jeans having the legs tied off at the bottom.

Cartridge filter

A cartridge filter unlike a bag filter is a depth filter with many layers for the filtration of the oil. It is part of the PLC automatic filtration system in which the oils make their way through the filter’s multiple layers for effective and efficient cleaning. There are many places for the unwanted particles to be caught and held in it.

Concluding Remarks

Mectech is India’s leading manufacturer and supplier of high pressure filtration system as well as PLC automatic filtration system meeting the needs of oil milling units. For a complete product portfolio, you can visit the company’s website.