180 Degree Bend Pipe Fitting

The ASME B16.9 elbow 180 degree belongs to a standard that governs the properties of NPS1/2 through NPS48. A 180-degree bend pipe fitting is use in between two lengths of pipe allowing a change of 180° directions. Elbow Fittings is occupied to change the direction of flow between two pipes. Common elbows are 90-, 60-, 45- and 22 ½-degree bends moreover are use to make a turn. Similarly, they can be join together to move around obstructions in the pipe run. Generally, elbows also are known as bends and are added to be in more than a few substances such as nickel alloys, stainless steel, alloy steel, carbon steel, duplex, high-quality duplex, etc. Also, steel pipe elbow (on occasion additionally known as bends) is a key part of a pressure piping machine operating to alternate the fluid float direction.

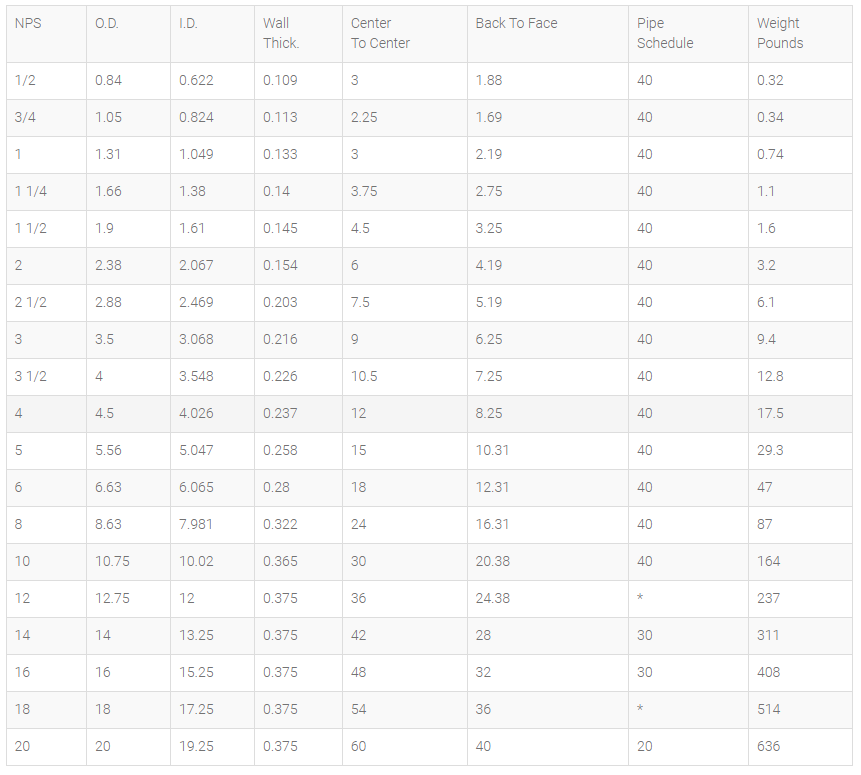

Hence, it is use to connect two pipes with the same or different nominal diameters, and to make the pipe and thus the fluid direction turn to a certain direction of 45 degrees or 90 degrees. Furthermore, a long Radius 180-degree return bend allows complete reversal of flow. The distance between the end of the elbow and the center line is 3 x NPS. A short radius 180-degree return bend allows complete reversal of flow but in a much tighter turn. Since the distance between the end of the elbow and the Centre line is 1 x NPS.

Stainless Steel 180 Degree Elbow Long Radius has a higher length and it makes the flow smooth by having a longer curve than the short radius.

There are different types of pipe fitting which are as follows:

Elbow, Reducer, Tee, Coupling, Adapters, Union, Valve, Cross, Olet, Cap, Plug, Swage Nipple, Expansion Joint, Bush, Long Radius Bend, Stream Traps, Flanges.

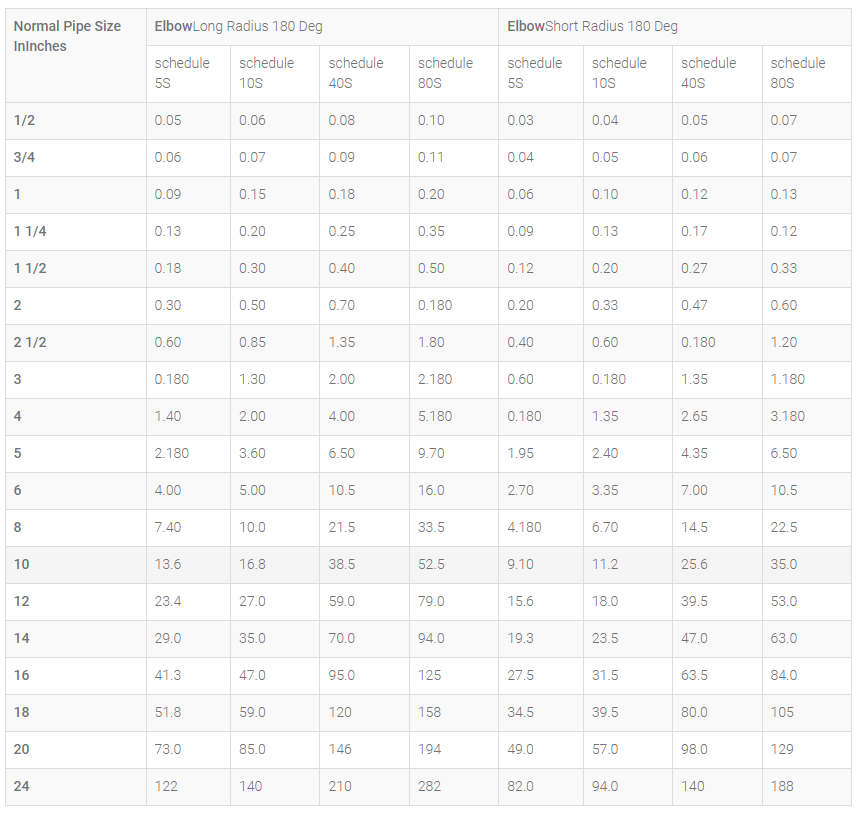

180 Degree Bend Elbow Pipe Fitting Dimension

Material:

- Carbon(CS) and galvanized steel

- Low-temperature carbon steel (LTCS)

- Impact-tested carbon steel (ITCS)

- Malleable iron

- Stainless steel(SS)

- Non-ferrous metals (includes Inconel, copper, Incoloy, and cupronickel)

- Chrome-molybdenum (alloy) steel (commonly used for high-temperature service)

- Non-metallic (includes acrylonitrile butadiene styrene(ABS), polyvinyl chloride(PVC), Fiber-reinforced (FRP), high-density polyethylene (HDPE), chlorinated polyvinyl chloride (CPVC), and toughened glass.

Connection Type:

- Threaded

- Clamp End

- End Bell

- Weld

- Flange

Type: Butt Weld (BW), Seamless (SMLS) Welded

Application:

- Chemical Industries

- Water Lines

- marine environment

Basically, the bodies of pipe & tube fittings are often equally with the same material. As the pipe or tube gets connected with each other e.g. copper, steel, PVC, CPVC, or ABS. Although any material allowed by the plumbing, health, or construction codes (as appropriate) may be used, it must be consistent with the other materials in the systems, the fluids being conveyed, and the temperature and pressure within (as well as outside) the system.

The 180 Degree Bend Pipe Elbow can be used with any type of piping as long as the dimensions and the mechanical property requirements match. The 180 Degree Street Elbow and the 180 Degree Compression Elbow are special classes of these elbows. 180 Degree Short Radius Elbow is applied in piping where the operational space is narrow and the pressure is not too high. ASME B16.9 Elbow 180 Degree comes in different materials such as carbon steel or other alloys.

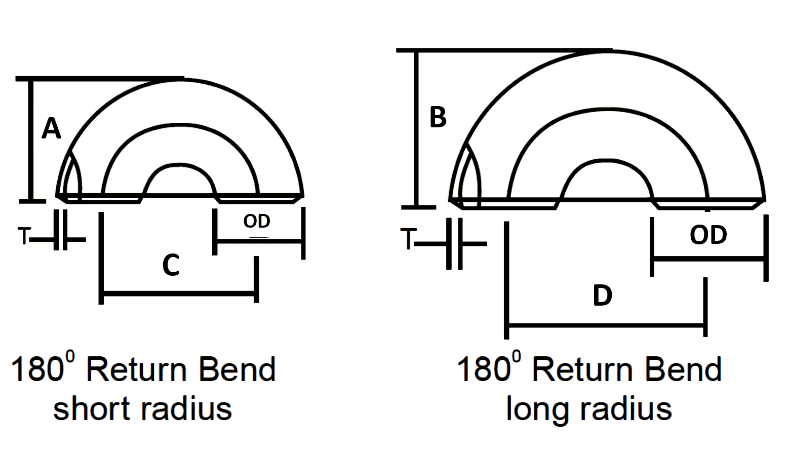

ANSI B16.9 180 Degree Bend Elbow Weight

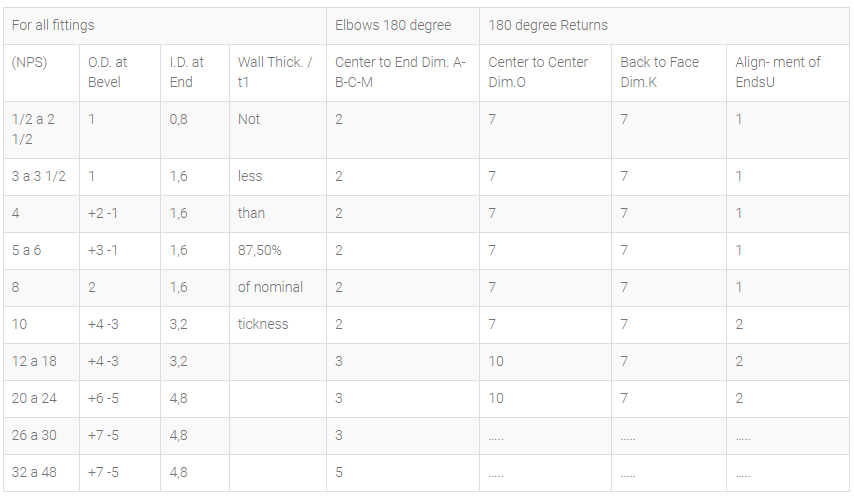

Dimensional Tolerance of 180 Degree Bend Elbow

180 Degree Bend Dimension