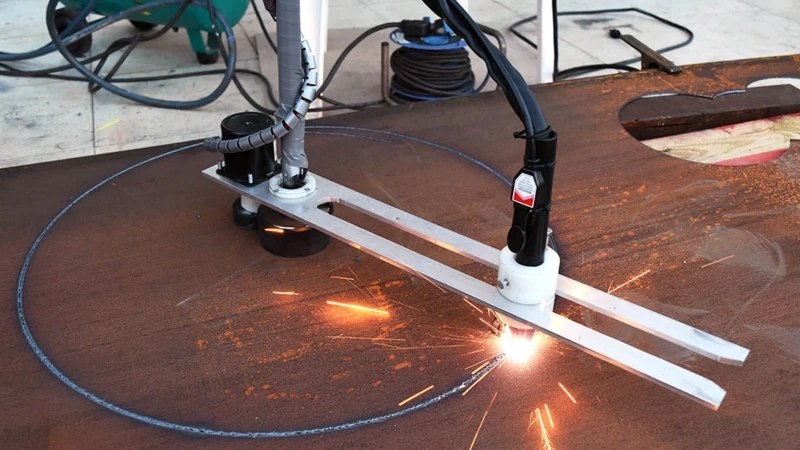

Plasma cutters are one of the most reliable ways to cast by sheet metal such as steel, stainless steel, brass, and aluminum. You can cut by metal with speed and accuracy as it heats within the metal with plasma. We have printed a guide to the top 10 points to study when picking a suitable plasma cutter for you. If you are fascinated by getting sheet metal to cut, check out the Online Proteus Store. If you would like more data about plasma cutters, take a glance at the plasma cutters consumers guide.

Air Compressor

Plasma cutters require compressed air to form the plasma. This can either be given by a built-in air compressor or an external tight air supply. Both of these kinds give significant effects, but you will require choosing which one is most suitable for you when picking a plasma cutter. A built-in air compressor will be more costly, but it means you will be able to handle small jobs faster.

Reliability

When picking a plasma cutter, you need a top-quality machine and will reach the test of time. Plasma cutters are not cheap, so you need to make sure your buying persists and does not break down when operating on something significant. Pick a committed brand from a trusted trader. Brands such as Hypertherm, Miller, Lincoln, and ESAB are already in the Bakers Gas store.

Pilot Arc

A pilot arc is a casting trait that gives a more stable angle with longer consumable life as you can cut metal without the point of the torch beating the metal. This is useful if you are cutting rusty assistance because you do not have to polish the metal and hit it. This is an almost new addition. However, most plasma cutters will have this trait except for the most inferior models.

Voltage

There are three distinct voltage choices that plasma cutters can be bought with. You can either get 115V, 230V, or a dual voltage cutter with both choices available. Plasma cutters with 115V are useful for novices that do not require much power and are casting at home. These can be filled into your standard household power outlet but do not give you that much control. If you have one with 230V input, then you will require a generator to run it. If you have both choices, you can switch the plug over-relying on how much power you require and your conditions.

Cut Rating

One of the most vital aspects to think about is the density of metal that a plasma cutter can cut. Consider the most thickness of metal you may be cutting and want a machine capable of it. If you are guaranteed, it is best to go for a high cut grade just in case.

There are three distinct cut ratings to view:

Rated Cut: The metal density can be cut at a rate of 10 inches per minute (IPM).

Quality Cut: The depth at a lower rate – this will be a thicker metal.

Sever Cut: The highest cut that can be obtained. This will be very quiet and may not be a precise cut.

Duty Cycle

The duty cycle leads to the number of users that a plasma cutter can last continuously. Plasma cutters with a more excellent duty cycle can be used for a more extensive point of time, and the duty cycle of any given machine will reduce as you raise the voltage. Look for the most crucial section number at any given amperage for the best service cycle.7.

Weight

Plasma cutters can scale from as little as 20lb right up to 100lbs for the tough industrial robots. If you need to sell your plasma cutter from job to job, you will need something you can have without putting your back out. Bear in thought, though, that the more moderate machines would not cut as heavy metal as a more extensive, more serious plasma cutter.

Cut quality

The cut quality is how clear and even the complete cut is. The best plasma cutters have an excellent cut quality, so cuts will seem sharp and clear and would not need you to give time blowing it up to have a standard form.

Operating cost

The consumption rate of a plasma cutter differs a lot between various tools and consumables. Research the consumption rate of your tools to help save money over time. Hypertherm plasma cutters are costly, but they have a lower running cost due to their best consumables, so that they may store your money in the long run.

Cutting Torch

The range of the torch is an essential factor. If you are going in a large mill and with a vast machine, you will require a longer torch so you can work in various areas of your workspace without having to leave the heavy plasma cutter about. If you are casting for long periods, then see at torches that fit your hand\'s form to help stop soreness.

Conclusion

Therefore, these are the factors that should be considered while purchasing the plasma cutter. Thus, before making any decision, you should visit and study many producers to make clear choices and decisions.